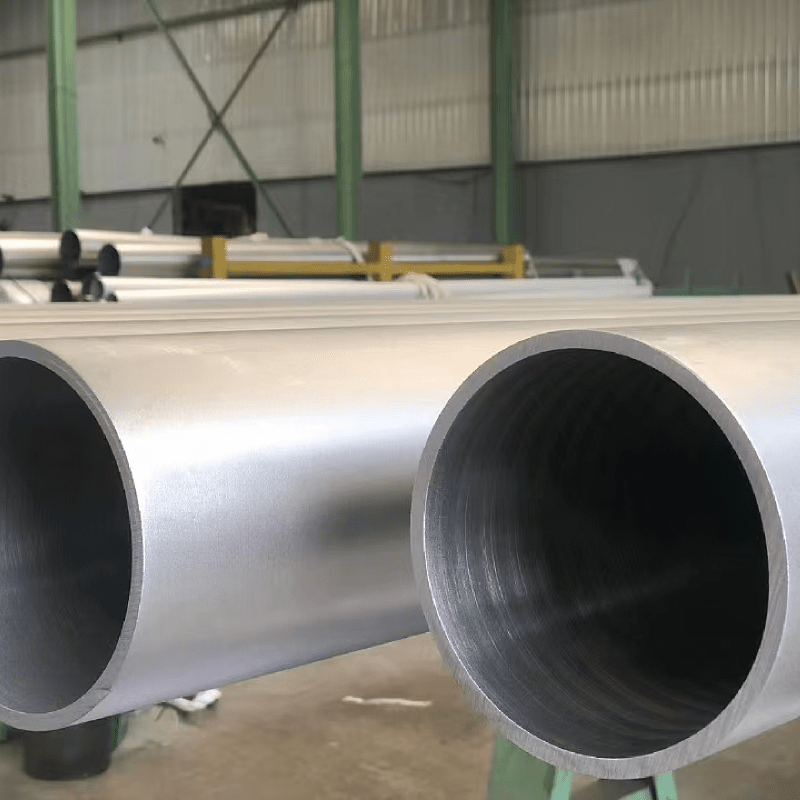

優れた耐食性と長寿命

3/8ステンレス鋼管は、高品質なステンレス鋼素材により、優れた耐食性を発揮します。この特性は、湿気や化学薬品、腐食性雰囲気にさらされる環境において特に価値があります。表面に形成されるクロム酸化物の不動態層が、酸化および化学的な攻撃から継続的に保護します。この自己修復型の保護層は損傷した場合でも自動的に再生し、追加の保護コーティングを必要とせず長期にわたって耐食性を維持します。管のピット腐食およびすきま腐食への耐性により、海洋環境、化学工場、屋外設置などでの使用に最適です。この本質的な耐食性により、メンテナンス頻度が減少し、耐用年数が延長されるため、投資価値が非常に高い製品です。