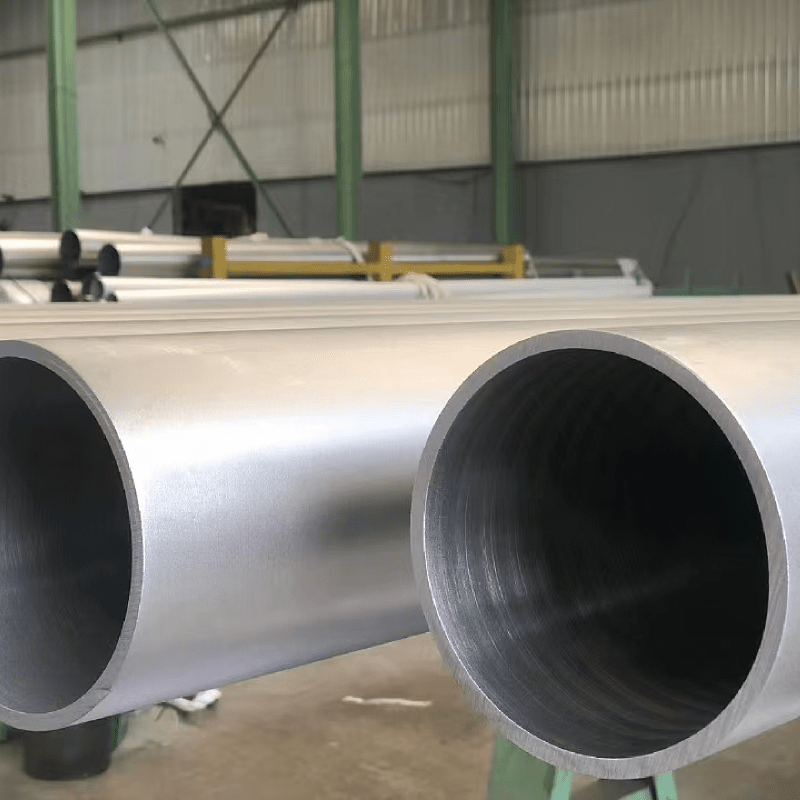

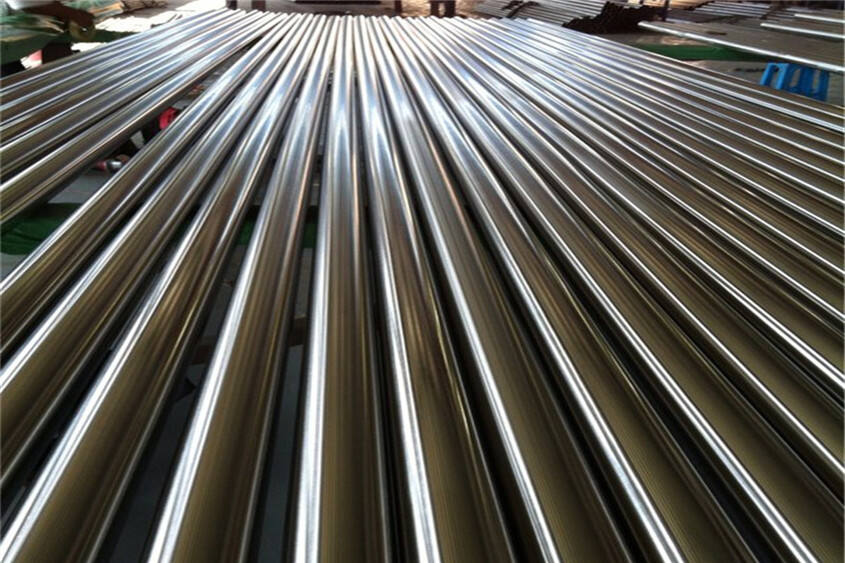

優れた耐食性と耐久性

ステンレス鋼製溶接管の優れた耐食性は、その最も重要な利点の一つです。この特性は、ステンレス鋼自体が持つ性質と高度な製造プロセスが組み合わさったもので、管表面に自己修復可能なクロム酸化物層を形成し、腐食性物質から継続的に保護することで、過酷な環境下でも長期的な性能を保証します。この自然な防護機構により、メンテナンスの必要性が大幅に低減され、配管システムの耐用年数が延びます。これらの管材は、点食、隙間腐食、応力腐食割れなどさまざまな劣化現象に対しても耐性があるため、耐久性がさらに高められています。この優れた耐久性により、交換頻度が減少し、ライフサイクル全体でのメンテナンスコストが低下するため、長期的な設置用途において費用対効果の高い選択肢となります。