先端製造精密

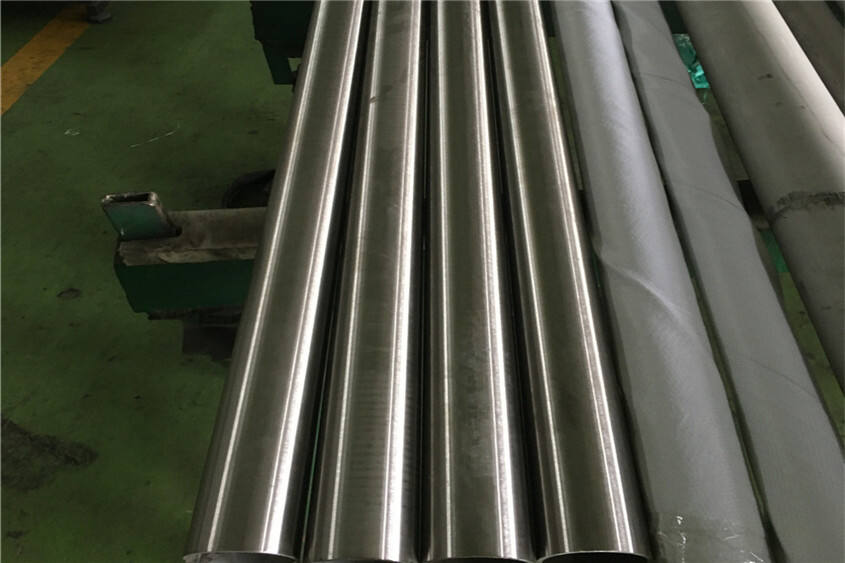

ステンレス鋼管の製造工程では、最新の生産技術を採用しており、生産されるすべての部品に求められる高精度を実現しています。コンピュータ数値制御(CNC)機械および自動溶接システムが完全に同期して動作し、生産プロセス全体で狭い公差と優れた一貫性を維持します。このレベルの精度は、設置時の適切な取付と運用時の最適な性能を確保するために不可欠です。3Dスキャンやデジタル測定機器を含む高度な品質管理システムにより、製造プロセスの各段階で寸法精度が確認されます。肉厚、直径、端面加工に対する正確な制御により、優れた継手の完全性を実現し、設置時の問題が発生する可能性を低減します。この製造精度は最終製品の品質を高めるだけでなく、材料の廃棄量削減およびコスト効率の向上にも寄与します。