뛰어난 재료 구성 과 내구성

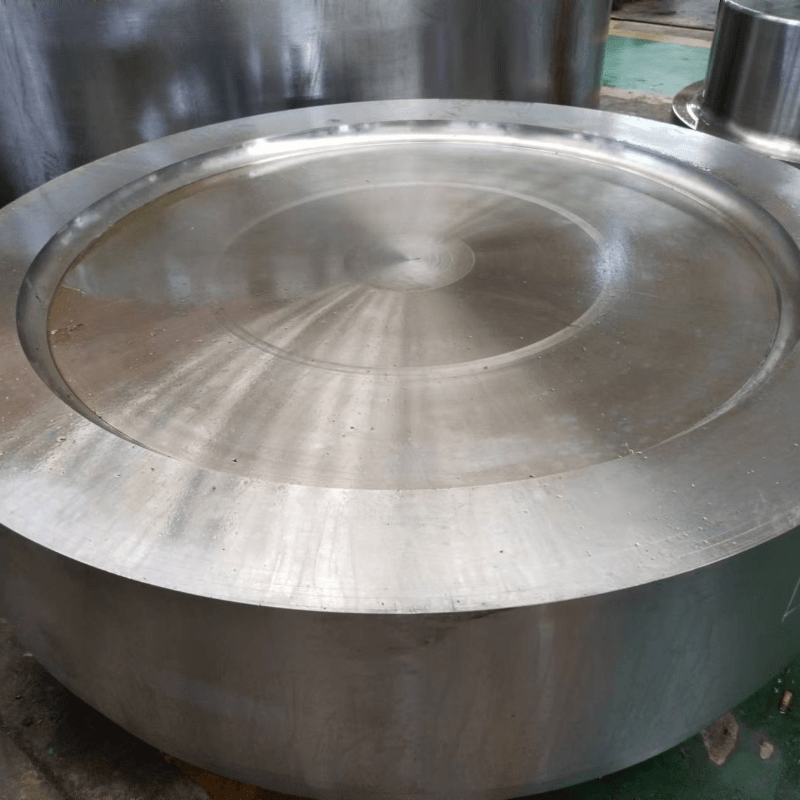

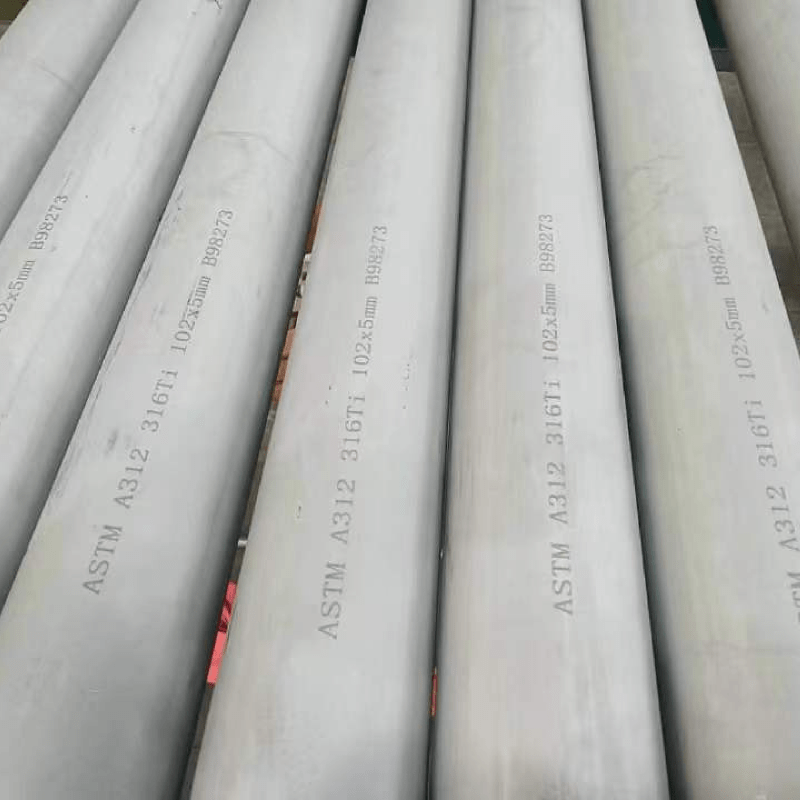

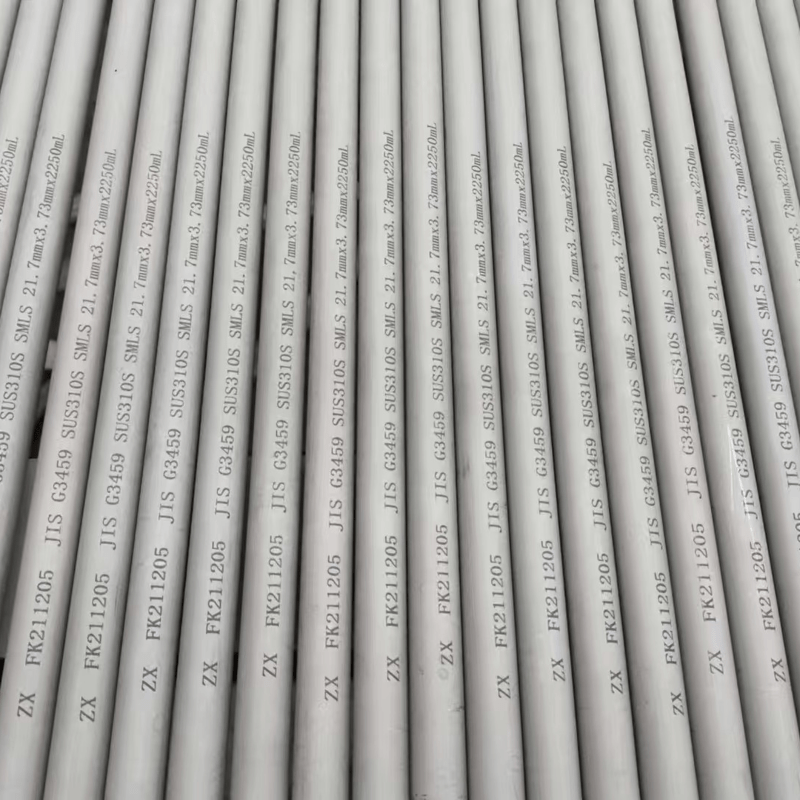

SS 피팅은 고품질 스테인리스강을 사용하여 제조되며, 뛰어난 강도와 내구성을 보장하는 정밀한 금속 조성을 포함합니다. 일반적으로 이러한 재료는 크로뮴과 니켈을 정교하게 균형 있게 배합하여 자체 치유가 가능한 불활성 층을 형성함으로써 탁월한 부식 저항성을 제공합니다. 이러한 첨단 금속 기술 덕분에 피팅은 강한 화학물질, 염수 및 극한 온도에 노출되더라도 구조적 무결성을 유지할 수 있습니다. 또한 최신 제조 공정을 통해 벽 두께와 응력 분포의 균일성을 확보함으로써 조기 파손을 방지하고 수명을 크게 연장시킵니다.