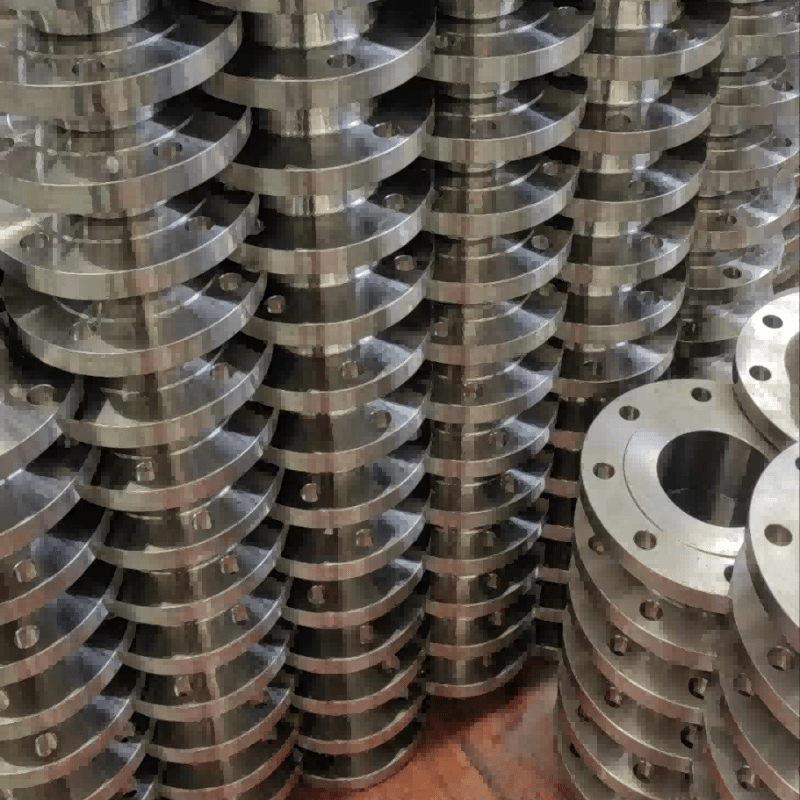

우수한 방청성 및 내구성

스테인리스강 피팅은 부식 저항성이 중요한 환경에서 우수한 성능을 발휘합니다. 합금에 포함된 크롬은 표면이 긁히거나 손상되더라도 지속적으로 부식으로부터 보호하는 자기 복원형 불활성층을 형성합니다. 이 뛰어난 내식성은 염수, 산성 및 알칼리성 용액을 포함한 다양한 부식성 매체에도 적용됩니다. 이 소재는 본래의 강도 덕분에 고압 및 고온 조건에서도 구조적 무결성을 유지하여 혹독한 산업용 응용 분야에 이상적입니다. 스테인리스강 피팅의 내구성은 유지보수 빈도를 줄이고 수명을 연장시켜 시스템 전체 수명 주기 동안 상당한 비용 절감 효과를 제공합니다.