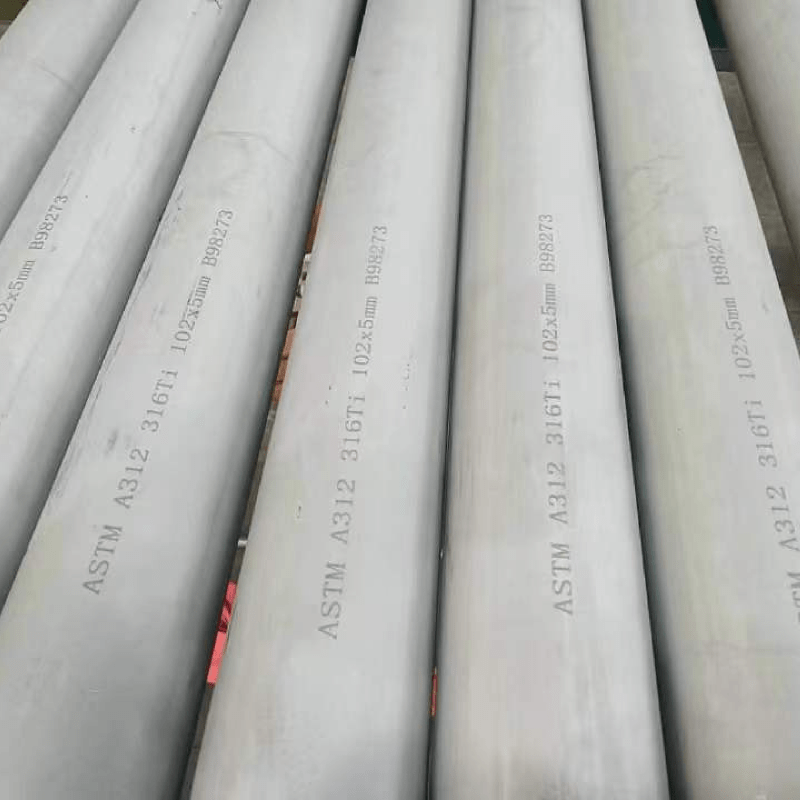

Superior Corrosion Resistance

Hastelloy C276 pipes exhibit unparalleled corrosion resistance across a broad spectrum of aggressive environments. The unique alloy composition, particularly the high molybdenum content, creates a passive film that provides exceptional protection against both oxidizing and reducing acids. This superior resistance extends to environments containing chlorides, sulfuric acid, and other highly corrosive media. The material's resistance to pitting and crevice corrosion makes it especially valuable in marine and chemical processing applications where conventional materials would rapidly deteriorate. The pipes maintain their protective properties even in the presence of contaminated process streams, ensuring reliable performance in complex chemical environments.