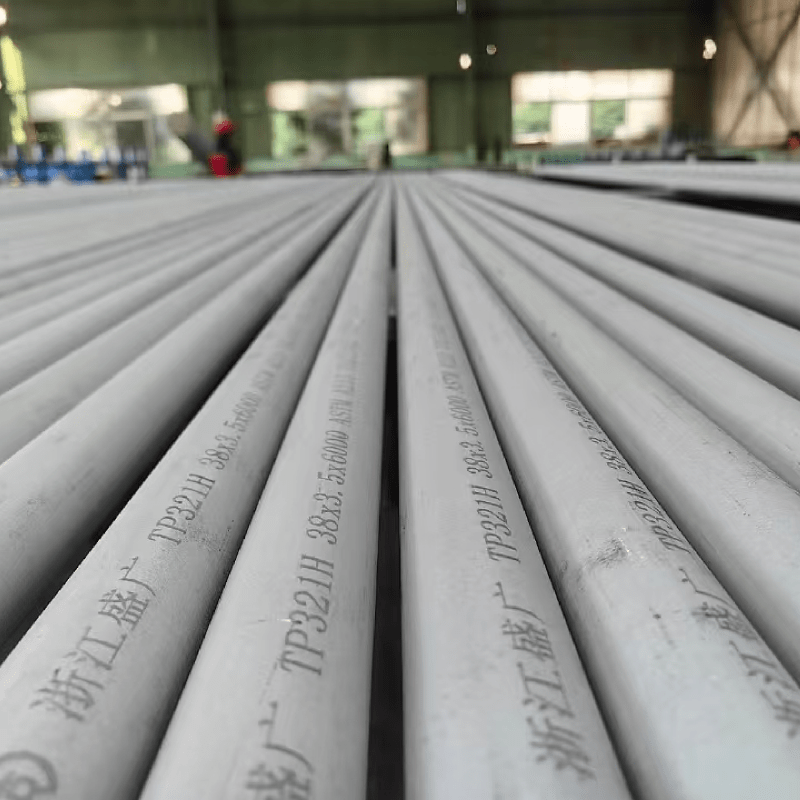

Superior Corrosion Resistance

Hastelloy fittings stand out primarily for their exceptional resistance to corrosion, a critical feature that sets them apart in the industrial fittings market. The unique metallurgical composition of Hastelloy creates an incredibly stable passive layer that provides unprecedented protection against a broad spectrum of corrosive media. This includes resistance to both oxidizing and reducing environments, chloride-induced stress corrosion cracking, and pitting corrosion. The material's ability to withstand aggressive chemicals such as hot concentrated mineral acids, organic acids, and chlorine-containing compounds makes it invaluable in chemical processing applications. This superior corrosion resistance translates to extended equipment life, reduced maintenance intervals, and enhanced safety in critical processes. The fittings maintain their structural integrity even when exposed to multiple corrosive agents simultaneously, a common challenge in industrial environments.