Resistência à Pressão e Integridade Estrutural Superior

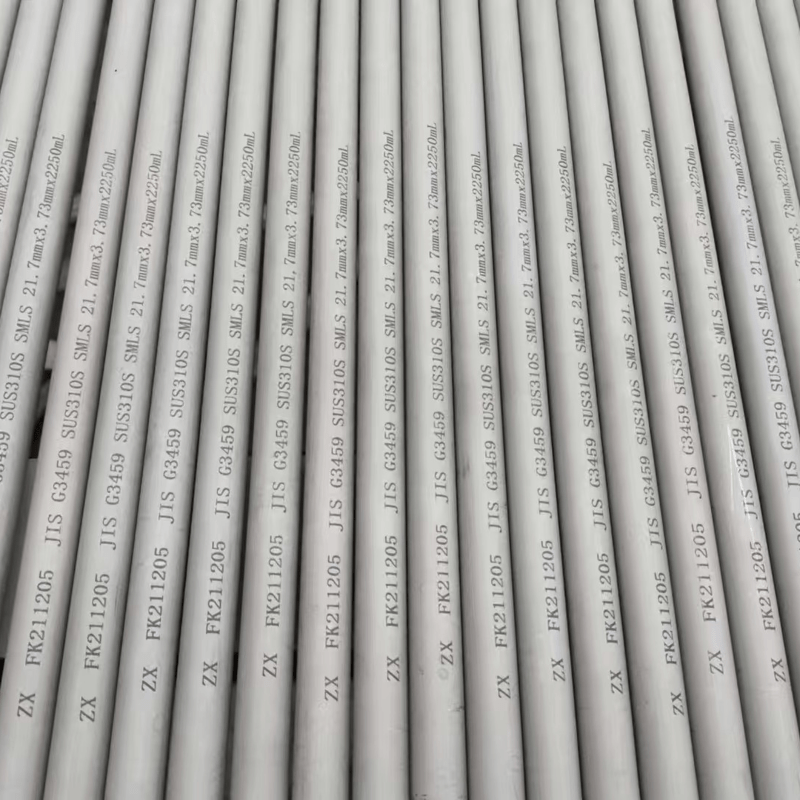

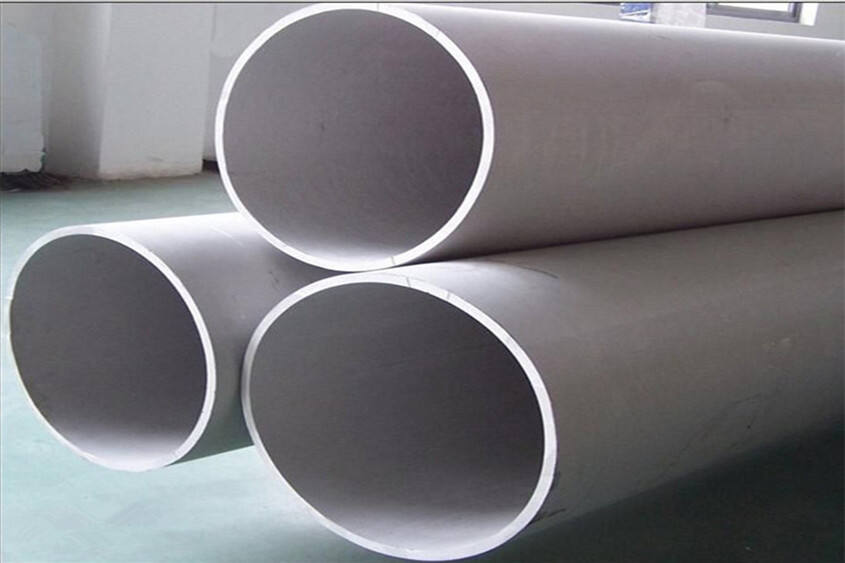

Tubos de aço inoxidável sem costura destacam-se em aplicações de alta pressão devido ao seu processo de fabricação exclusivo, que elimina pontos fracos normalmente encontrados em tubos soldados. A estrutura contínua e ininterrupta distribui uniformemente as cargas de pressão por toda a parede do tubo, reduzindo significativamente o risco de falha. Essa resistência superior à pressão é obtida por meio de um sofisticado processo de conformação a quente que garante um alinhamento molecular uniforme em todo o material. A ausência de costuras de solda elimina pontos de concentração de tensão, tornando esses tubos capazes de suportar pressões operacionais muito mais altas do que os seus equivalentes soldados. Esse recurso é particularmente crucial em sistemas hidráulicos, transporte de gás sob alta pressão e processos industriais críticos, onde uma falha no sistema poderia ter consequências graves.