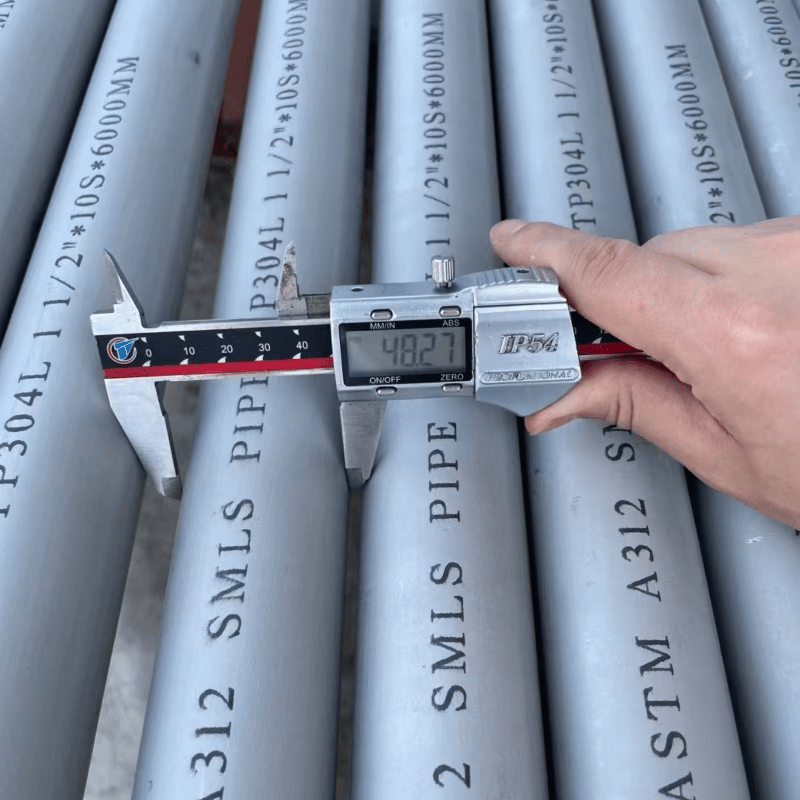

우수한 방청성 및 내구성

1 1 4 스테인리스강 튜빙의 뛰어난 내식성은 정교하게 설계된 금속조성에 기인한다. 높은 크롬 함량은 스스로 치유되는 불활성층을 형성하여 표면을 부식성 물질로부터 지속적으로 보호하며, 혹독한 환경에서도 장기적인 신뢰성을 보장한다. 이 고유한 내식성은 산, 알칼리, 염용액 등 다양한 부식성 매체에도 적용되어 다방면의 산업용 응용 분야에 적합하다. 이 소재는 고온에서의 산화 저항성으로 인해 내구성이 더욱 향상되며, 열악한 운전 조건에서도 구조적 완전성을 유지한다. 이러한 내식성과 내구성의 조합은 최종 사용자에게 유지보수 비용 절감, 서비스 수명 연장 및 운영 신뢰성 향상을 제공한다.