費用対効果の高い品質保証

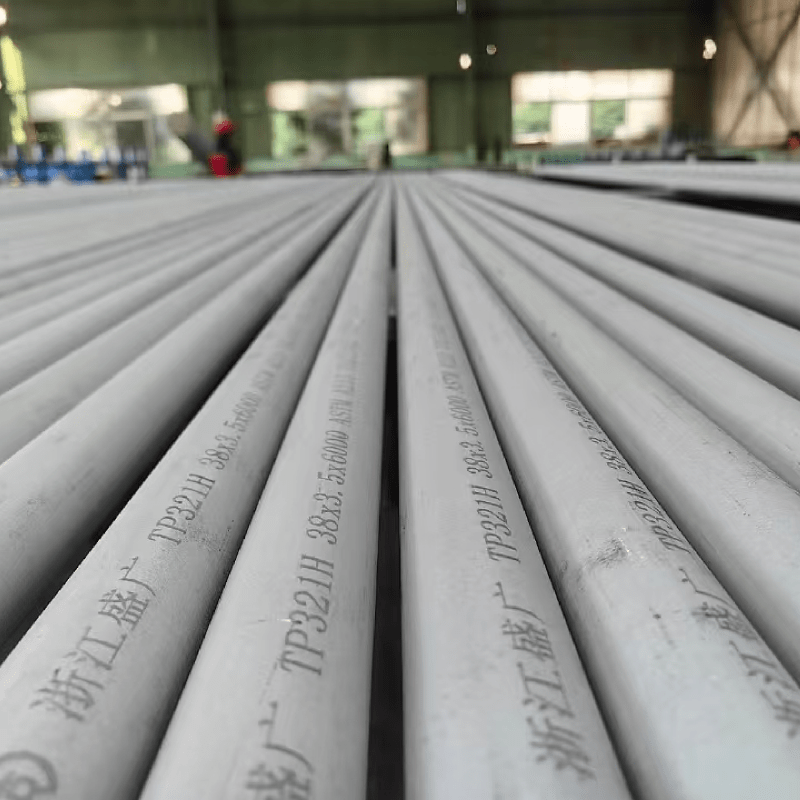

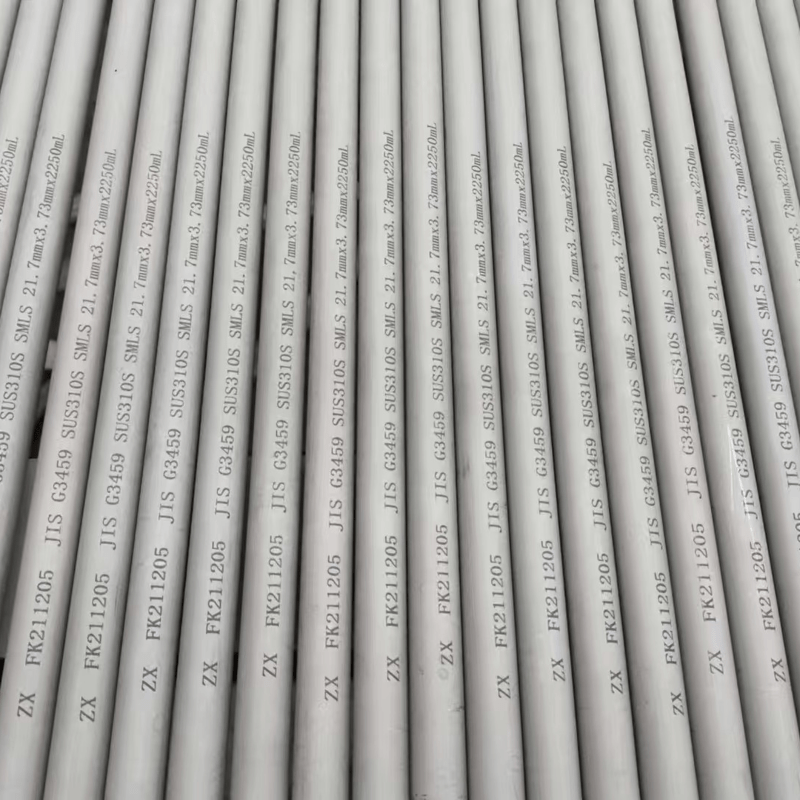

ステンレスパイプの価格構造には、長期的な信頼性と性能を保証する包括的な品質保証措置が含まれています。各パイプは圧力試験、材料組成分析、寸法精度検査などの厳格な試験および認証プロセスを経ており、これらの品質管理措置は価格に組み込まれているため、顧客は投資に対する確実性を得られます。標準化された試験手順により、異なる製造ロット間でも一貫した品質が維持され、性能のばらつきリスクが低減されます。価格は高度な試験装置や有資格スタッフの活用を反映しており、各パイプが業界基準を満たすかそれ以上であることを保証しています。この体系的な品質管理アプローチにより、重要な用途における高コストな故障やダウンタイムを防ぐことができます。