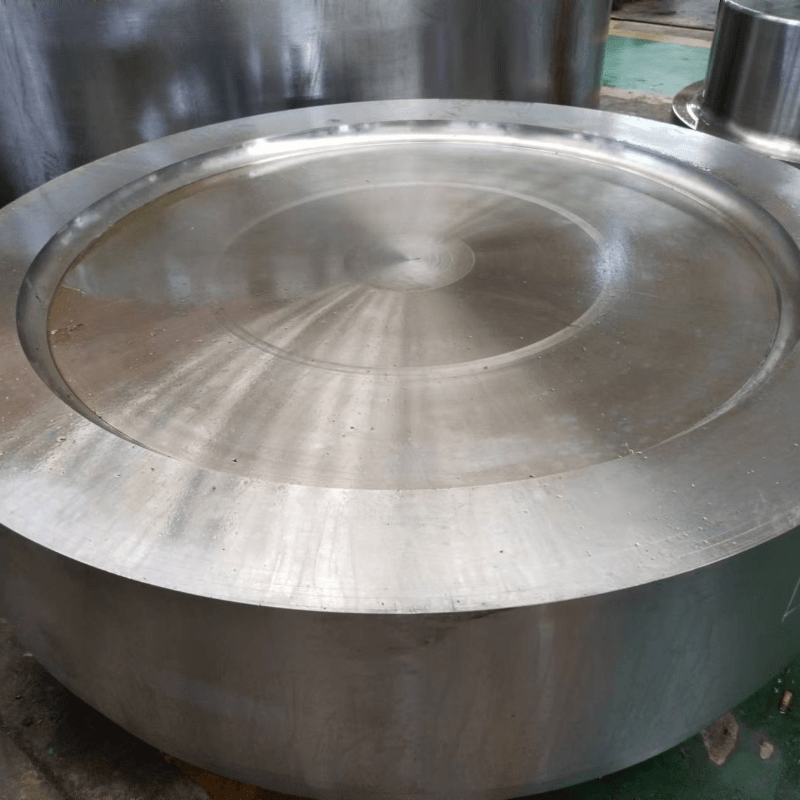

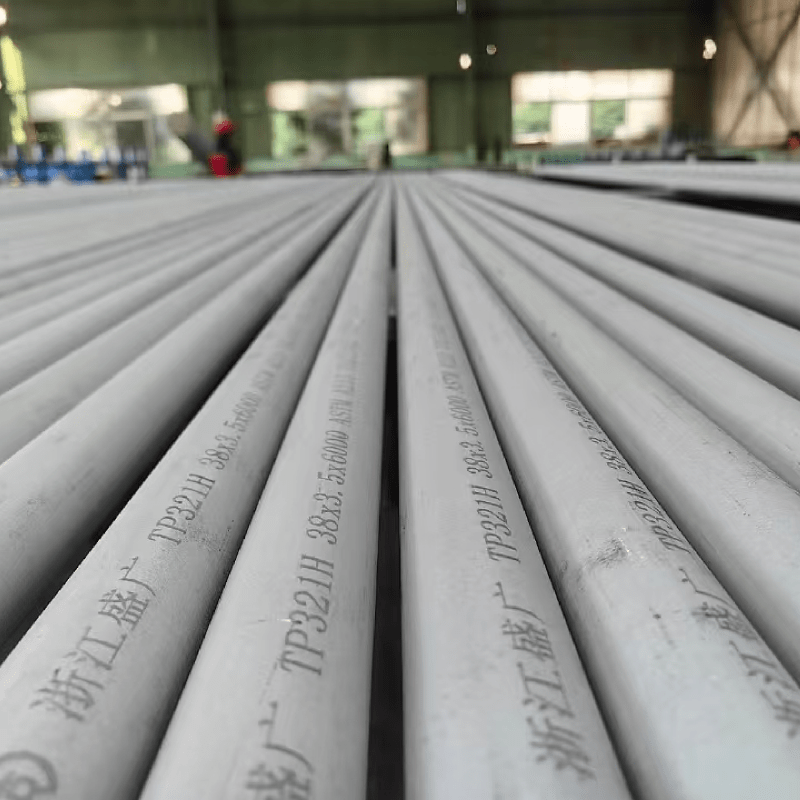

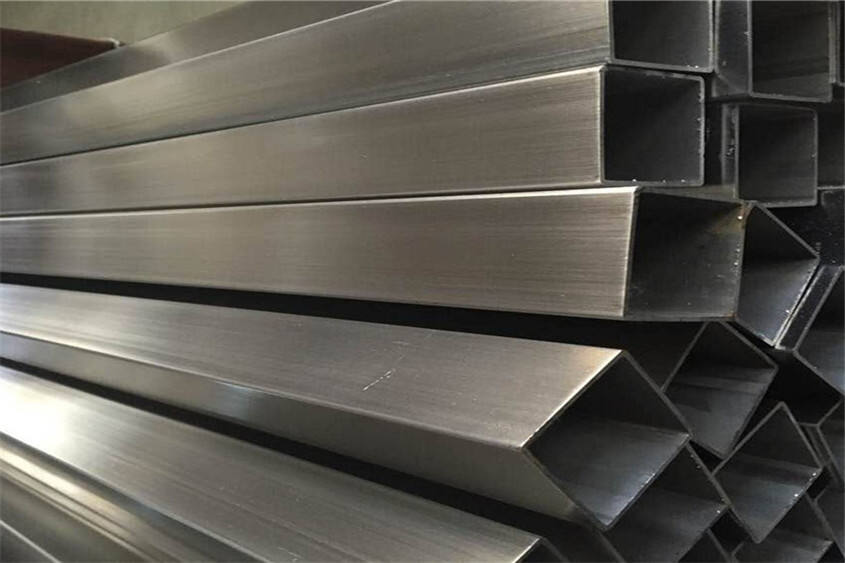

مقاومة ممتازة للتآكل والمتانة

يُعزى التحمل الاستثنائي لأنابيب المواسير والتجهيزات المصنوعة من الفولاذ المقاوم للصدأ تجاه التآكل إلى تركيبها الغني بالكروم، والذي يُشكّل طبقة سلبية تُصلح نفسها تلقائيًا وتحمي باستمرار من الأكسدة والهجمات الكيميائية. هذه الخاصية المتأصلة تلغي الحاجة إلى طلاءات حماية إضافية، مما يقلل من تكاليف التركيب والصيانة ويضمن موثوقية طويلة الأمد. ويمتد تحمّل هذه المادة إلى مختلف البيئات التآكلية، بما في ذلك الأجواء البحرية، ومرافق المعالجة الكيميائية، والظروف ذات الرطوبة العالية. كما يتم تعزيز متانة هذه المكونات بفضل قوتها الشد العالية وقدرتها على تحمل الصدمات، ما يمكنها من مقاومة الإجهادات الميكانيكية الكبيرة وتقلبات الضغط دون أن تتدهور. ويؤدي هذا التوفيق المتميز بين الخصائص إلى أنظمة تحافظ على سلامتها الهيكلية وخصائص أدائها طوال عقود من الخدمة، ما يجعلها استثمارًا اقتصاديًا في التطبيقات الحرجة.