تقنية الختم المتفوقة

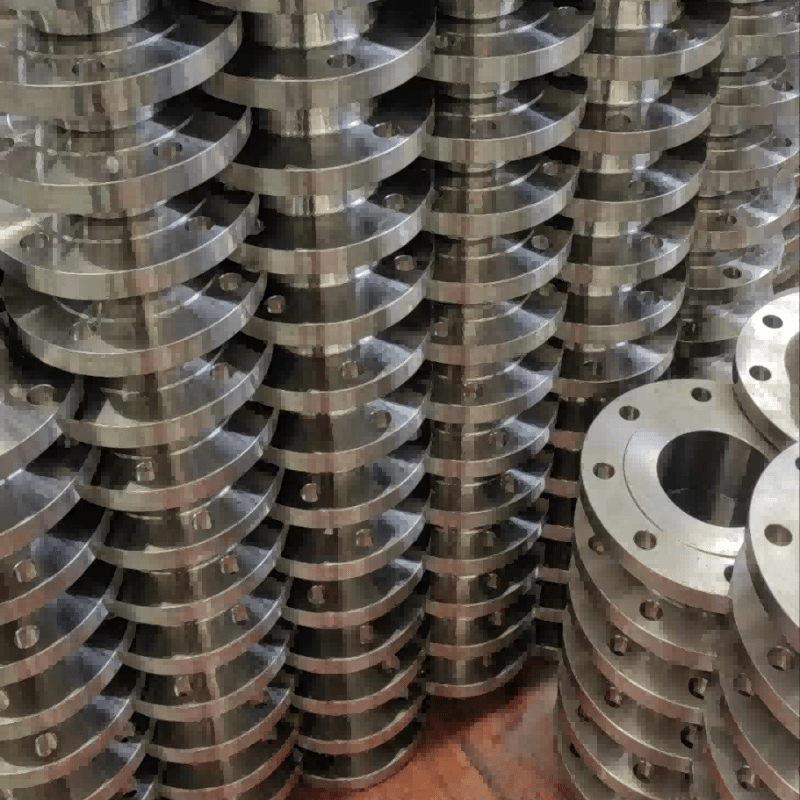

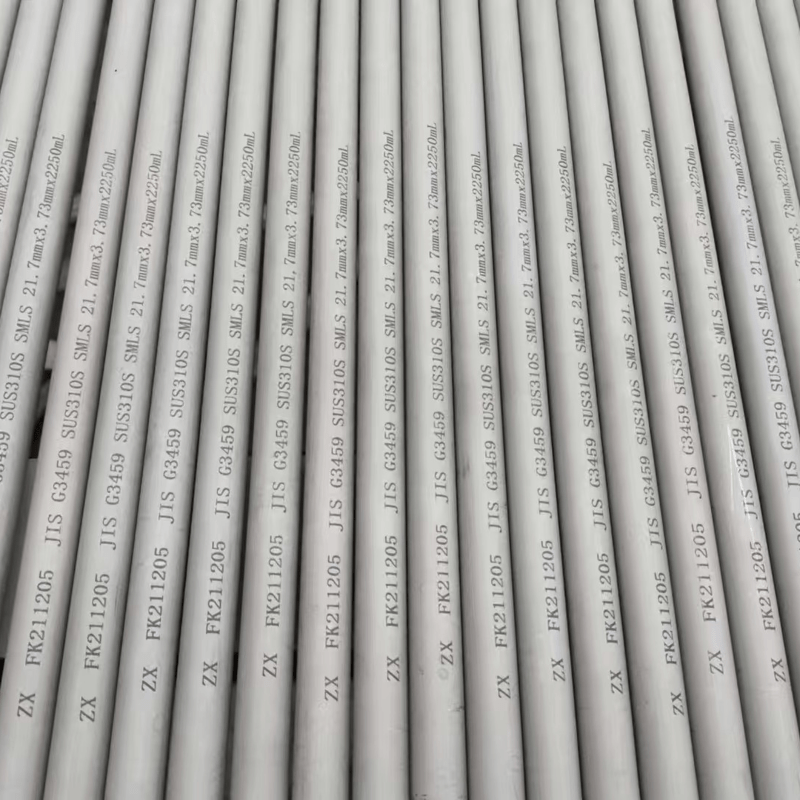

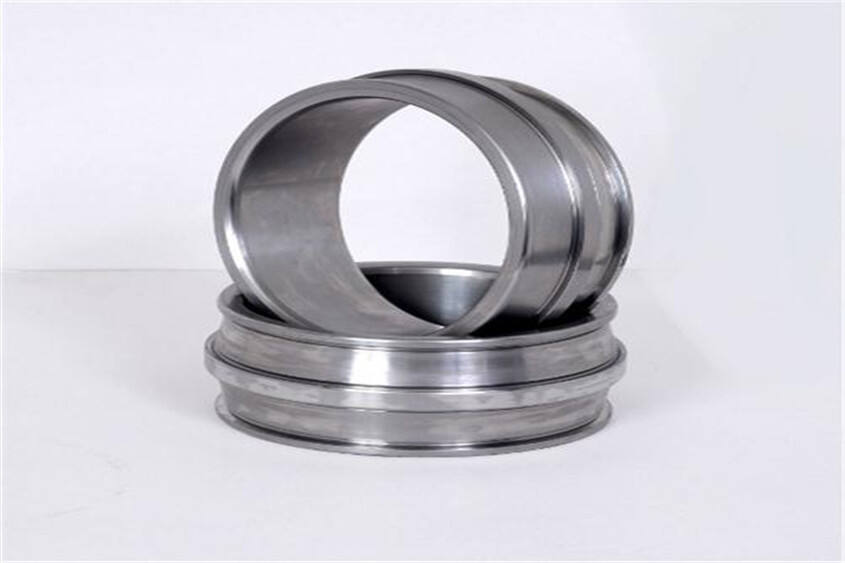

إن التكنولوجيا المتقدمة للإغلاق المستخدمة في أنظمة الأنابيب والشفاه الحديثة تمثل قفزة كبيرة إلى الأمام في مجال التعامل مع السوائل في القطاعات الصناعية. يتضمن التصميم أسطح إغلاق مُصنَّعة بدقة ومواد ختم متقدمة تعمل معًا على إنشاء حائل ضد التسرب موثوق للغاية. تستخدم هذه التكنولوجيا تقنيات خاصة في إنهاء السطح تضمن اتصالًا مثاليًا بين أوجه الشفاه ومواد الختم، مما يخلق إغلاقًا يحتفظ بسلامته تحت ظروف ضغط وحرارة متغيرة. يتم تحقيق قدرة النظام على الحفاظ على إغلاقات محكمة حتى في ظروف التشغيل القاسية من خلال اختيار دقيق للمواد وتسامح تصنيعي دقيق. هذه الميزة بالغة الأهمية بشكل خاص في التطبيقات التي تتضمن مواد خطرة أو أنظمة ذات ضغط عالٍ، حيث يُعد منع التسرب أمرًا بالغ الأهمية لضمان السلامة وحماية البيئة.