تكوين مواد ومهندسية أفضل

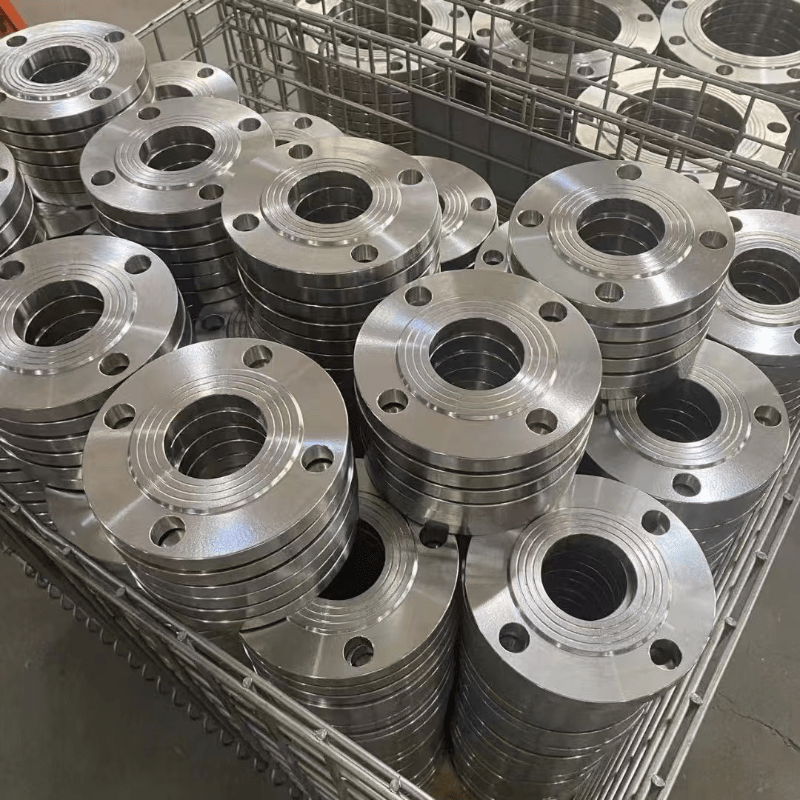

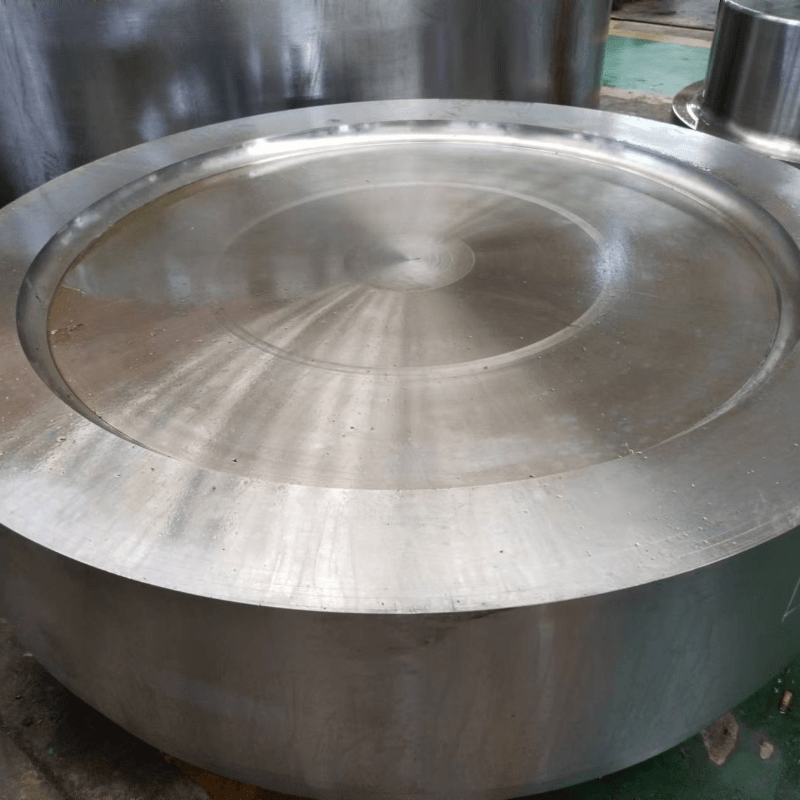

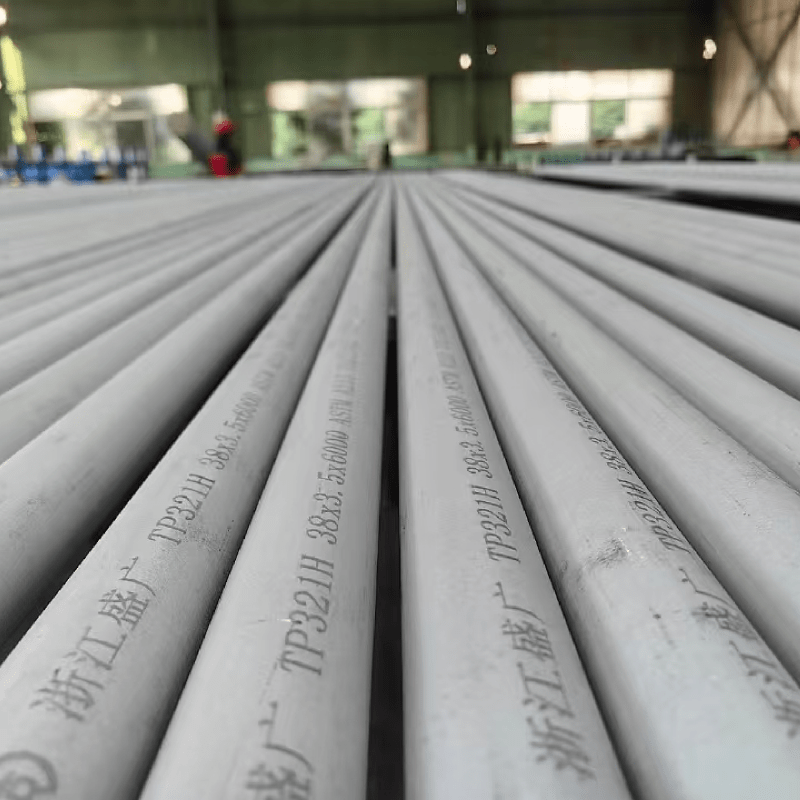

تصنع الشفاه الفولاذية باستخدام مواد فولاذية من الدرجة الممتازة، يتم اختيارها بعناية لتلبية متطلبات التطبيق المحددة. تخضع تركيبة المادة لاختبارات دقيقة لضمان الخصائص الميكانيكية المثلى، بما في ذلك مقاومة الشد، ومقاومة الخضوع، ومقاومة الصدمة. تُحسّن العمليات المعدنية المتقدمة من قدرة الشفة على تحمل درجات الحرارة والضغوط القصوى مع الحفاظ على الثبات الأبعادي. يدمج التصميم الهندسي حسابات دقيقة لتوزيع الإجهاد، مما يضمن تحمل الحمل بشكل موحد ومنع تركز الإجهاد في مناطق معينة. تشمل إجراءات ضمان الجودة أثناء الإنتاج اختبارات بالموجات فوق الصوتية، وفحصًا إشعاعيًا، وفحصًا للسطح الخارجي لكشف أي عيوب أو عدم اتساقات محتملة. هذا النهج الشامل في اختيار المواد والتصميم الهندسي ينتج منتجًا يقدّم أداءً وموثوقية استثنائيين في البيئات الصناعية الصعبة.