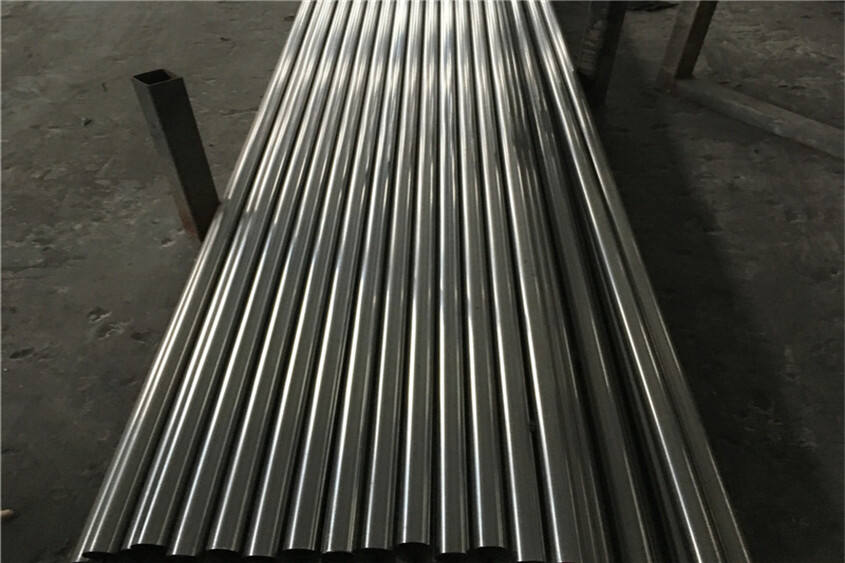

مقاومة التآكل العالية

ينبع مقاومة أنبوب الفولاذ المقاوم للصدأ 316L الاستثنائية للتآكل من تركيبته الكيميائية المصممة بعناية، ولا سيما احتوائه على الموليبدنوم ونسبة أعلى من النيكل. ويؤدي هذا التركيب إلى تكوين طبقة سلبية تُصلح نفسها تلقائيًا وتحمي المادة باستمرار من مختلف البيئات المسببة للتآكل. وتُعدّ قدرة الأنبوب على تحمل الهجمات الناتجة عن الكلوريدات والحمضيات والمحاليل القلوية أمرًا لا يُقدَّر بثمن في معالجة المواد الكيميائية والتطبيقات البحرية والبيئات التي تفشل فيها أنواع الفولاذ المقاوم للصدأ القياسية. ويمنع المحتوى المنخفض من الكربون حدوث التحسس أثناء اللحام أو التعرّض لدرجات الحرارة العالية، مما يحافظ على سلامة خصائص مقاومة التآكل في الهيكل بأكمله. وتُعد هذه الخاصية بالغة الأهمية في التطبيقات التي قد يؤدي فيها فشل المادة إلى عواقب كارثية، مثل تصنيع الأدوية أو المنشآت العاملة في المياه العميقة.