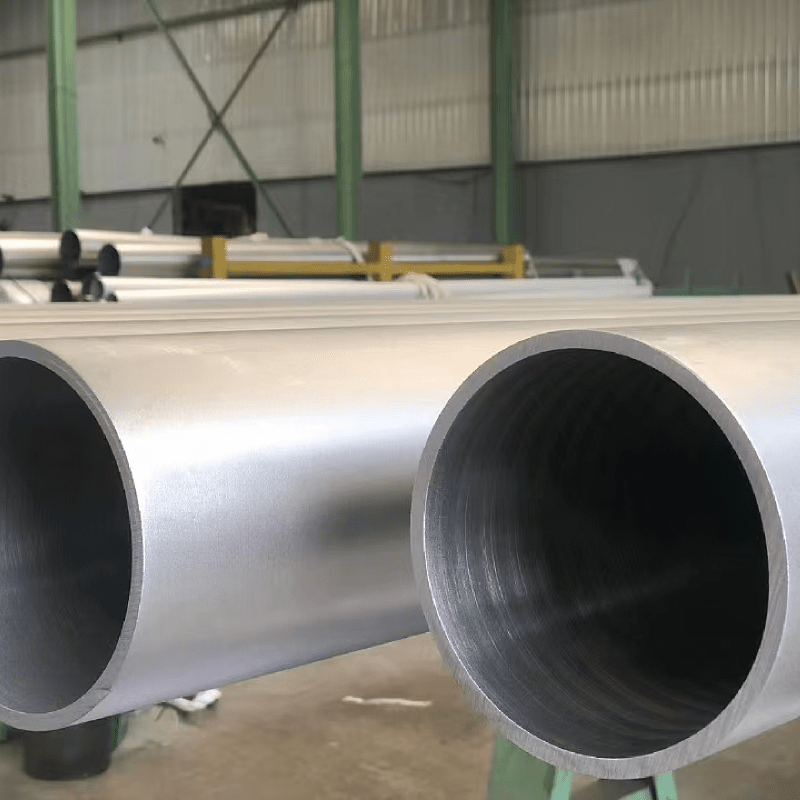

Superior Corrosion Resistance and Durability

The exceptional corrosion resistance of stainless steel welded tubes stands as one of their most significant advantages. The inherent properties of stainless steel, combined with precise welding techniques, create a uniform surface that effectively resists various forms of corrosion, including pitting and crevice corrosion. This resistance is particularly valuable in applications exposed to harsh environmental conditions, chemical processes, or marine environments. The tubes maintain their structural integrity and appearance over extended periods, significantly reducing replacement frequency and maintenance costs. The durability of these tubes is further enhanced by their ability to withstand extreme temperatures without degradation of their mechanical properties, making them suitable for both high-temperature and cryogenic applications.