Advanced Manufacturing Technology

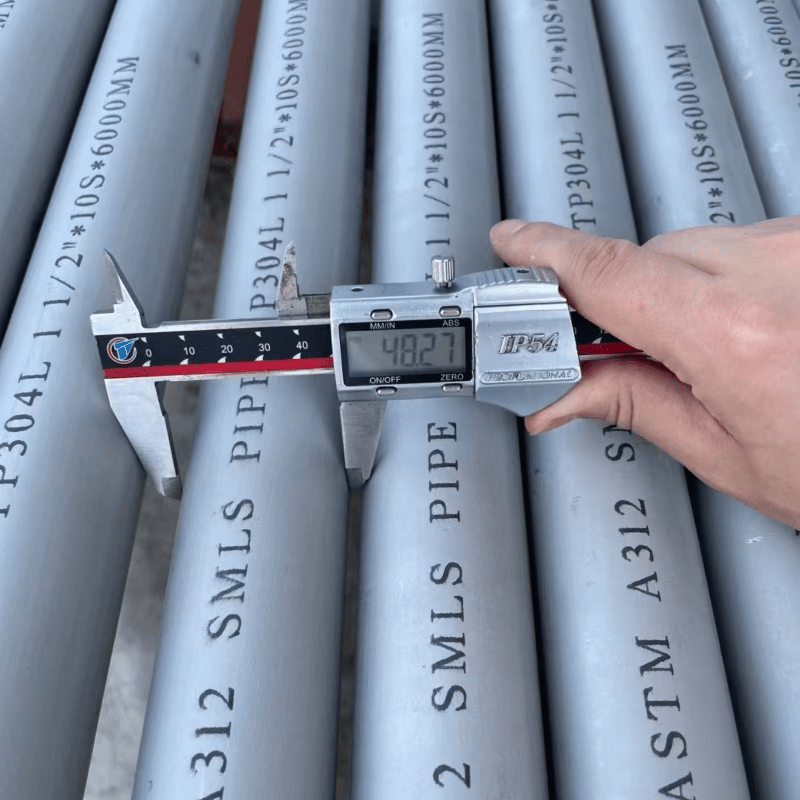

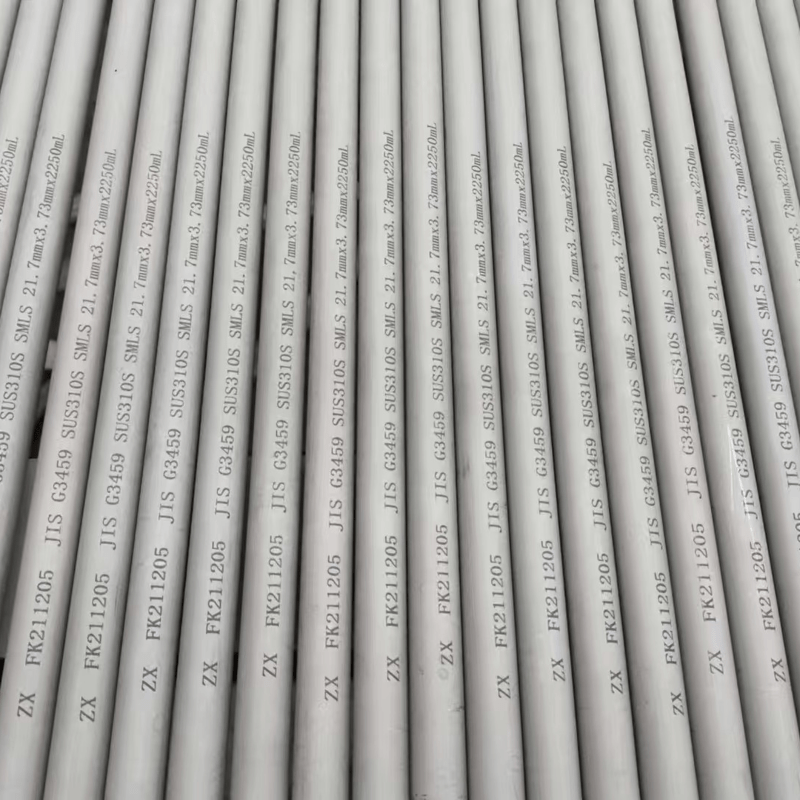

Modern stainless steel pipe manufacturers leverage cutting-edge manufacturing technology to ensure superior product quality and consistency. Their production facilities incorporate automated systems that maintain precise control over critical parameters throughout the manufacturing process. Advanced welding technologies, including automated orbital welding systems, ensure consistent weld quality and structural integrity. These manufacturers employ sophisticated quality control equipment, such as ultrasonic testing devices and X-ray inspection systems, to detect any potential defects. The integration of computer-controlled machinery allows for precise dimensional control and surface finishing. This technological advancement enables manufacturers to achieve tighter tolerances and better surface finishes than ever before.