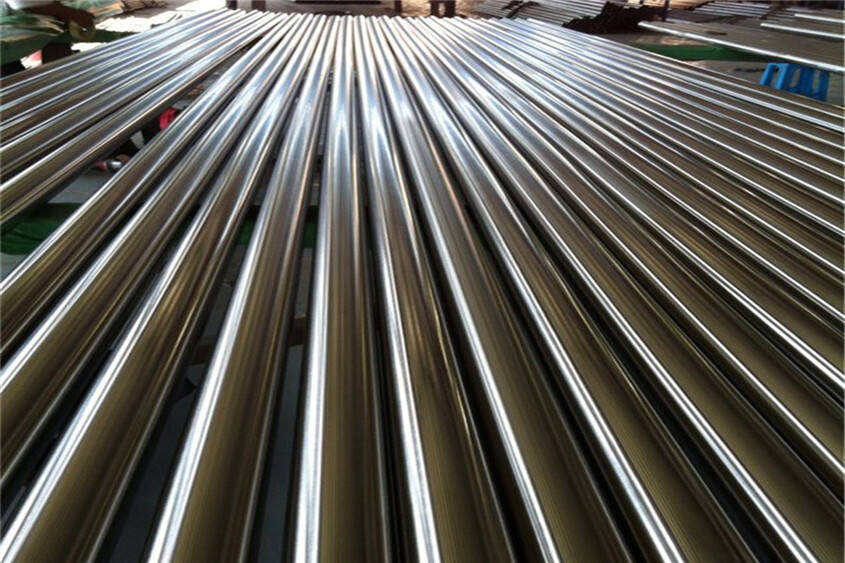

Superior Corrosion Resistance

The exceptional corrosion resistance of Inconel 625 tubes stands as one of their most remarkable features, particularly in aggressive chemical environments. This superior resistance stems from the carefully balanced composition of nickel, chromium, and molybdenum, which forms a stable, self-healing passive oxide layer on the surface. This protective layer provides outstanding defense against various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. In marine environments, where chloride-induced corrosion poses a significant challenge, these tubes demonstrate remarkable resilience, maintaining their structural integrity even after prolonged exposure to saltwater and harsh marine conditions. The material's resistance extends to both oxidizing and reducing environments, making it versatile for various chemical processing applications. This comprehensive corrosion resistance significantly reduces the risk of unexpected failures, extends equipment lifespan, and minimizes maintenance requirements, resulting in substantial cost savings over the lifecycle of the equipment.