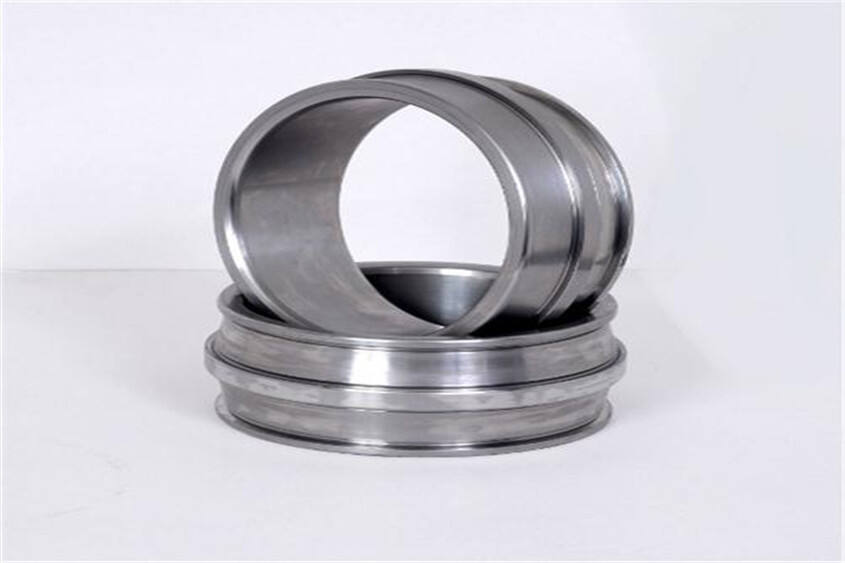

Superior Sealing Performance

The exceptional sealing capabilities of blind flanges represent a cornerstone of their design and functionality. These components utilize precision-engineered surfaces and carefully calculated bolt patterns to achieve optimal compression distribution across the gasket interface. This design ensures consistent and reliable sealing performance under various operating conditions, including extreme temperatures and high-pressure environments. The sealing mechanism is enhanced by the uniform stress distribution achieved through proper torque application, preventing localized stress concentrations that could compromise seal integrity. Modern blind flanges often incorporate advanced surface finishing techniques that improve gasket compatibility and reduce the likelihood of leakage. This attention to detail in sealing performance makes blind flanges particularly valuable in applications where containment of hazardous materials is critical.