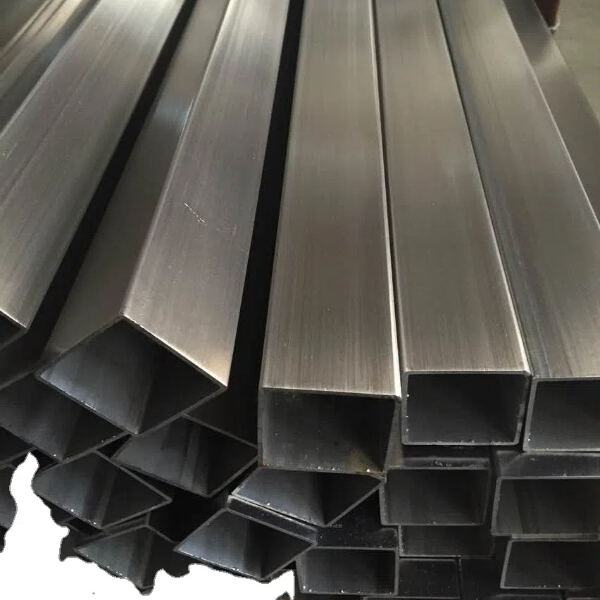

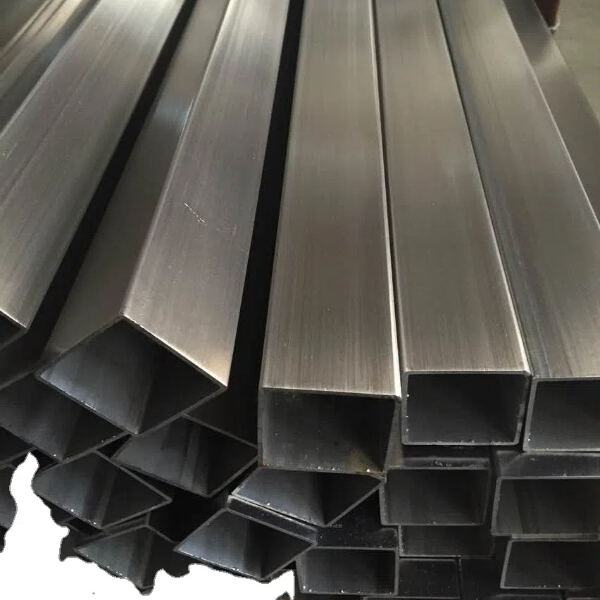

Tubos e Canos de Aço Inoxidável ASTM/ASME 17-7 PH são produtos semi-austeníticos endurecidos por precipitação (UNS S17700) que atendem aos padrões ASTM A312/A213/A790, com uma composição precisamente engenhada de cromo (16-18%), níquel (6,5-7,75%) e alumínio (0,75-1,5%) para proporcionar excelente resistência (até 1450 MPa em esforço de rendimento na condição TH1050) e resistência à corrosão comparável ao aço inoxidável 304. Esta liga de alto desempenho alcança suas propriedades ótimas através de um processo único de tratamento térmico em três etapas (solution annealing, condicionamento e envelhecimento), tornando-a particularmente adequada para molas aeroespaciais, instrumentos cirúrgicos e vasos de pressão onde são necessários ultra-alta resistência e resistência à fadiga. O material oferece excelente tenacidade tanto em temperaturas criogênicas quanto elevadas (até 315°C/600°F em serviço contínuo), com excelente resistência à fissuração por corrosão por tensão e à oxidação. Aplicações típicas incluem tubulações hidráulicas para aviões, componentes de reatores nucleares e fixadores sob alta tensão, onde a combinação das propriedades mecânicas do 17-7 PH, formabilidade na condição anelada (Condição A) e capacidades subsequentes de endurecimento por envelhecimento fornecem aos engenheiros flexibilidade de design sem precedentes para componentes críticos. Disponível em várias condições metalúrgicas (RH950, TH1050, etc.) para atender a requisitos específicos de desempenho enquanto mantém resistência à corrosão comparável às ligas austeníticas em grande parte dos ambientes.

|

|