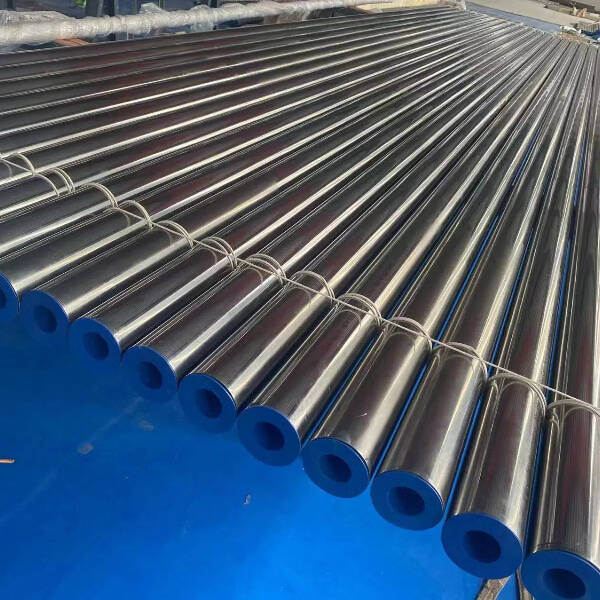

ASTM/ASME 440F Roestvrij Staal Buizen & Tubes zijn vrije snijmachines martensitisch (UNS S44020) producten die voldoen aan ASTM A213/A268 normen, met een zwavel-verhoogde (min. 0,15%) hoog-koolstof (0,95-1,20%) chroom (16-18%) samenstelling die de extreme hardheid van 440C roestvrij staal combineert (tot 62 HRC wanneer hittebehandeld) met verbeterde bewerkbaarheid voor precisie-asdelen en snijdgereedschappen. Deze specialiteitsgraad behoudt de uitzonderlijke slijtage-weerstand van 440-serie allianties terwijl superieure chips vorming en oppervlaktekwaliteit wordt bereikt in CNC operaties, hoewel er een beperkte reductie is in dwarse mechanische eigenschappen. Hoofdzakelijk gebruikt voor hoogprestatiebewerkte onderdelen in plaats van druktoepassingen, dienen 440F roestvrij staal buizen cruciale rollen in luchtvaartmechanismen, chirurgisch instrumentenproductie, en precisie-as systemen waar complexe geometrieën zowel ultra-hoge hardheid (Rc 54-60 typisch dienstbereik) als productie-efficiëntie vereisen, wat zorgvuldige hittebehandeling na bewerking vereist om corrosieweerstand en dimensionele stabiliteit te optimaliseren in eisende dienstomgevingen.