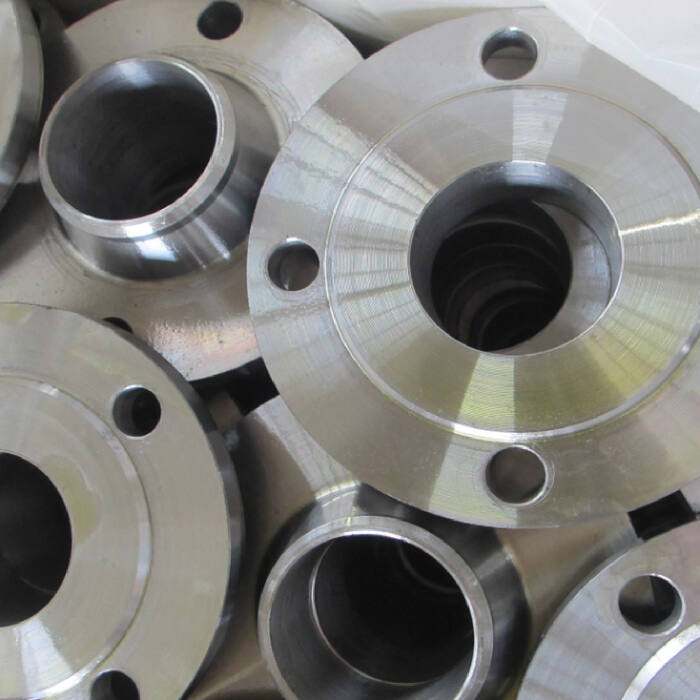

A slip - on - weld flange is a crucial component in piping systems. It features a neck that smoothly transitions from the flange face to the pipe end, enhancing the strength and integrity of the connection.

Description:

A slip - on - weld flange is a crucial component in piping systems. It features a neck that smoothly transitions from the flange face to the pipe end, enhancing the strength and integrity of the connection. This type of flange is designed for butt - welding to the pipe, providing a seamless and leak - resistant joint. Made from materials like carbon steel, stainless steel, etc., it can withstand high pressures and temperatures, depending on the material grade and design. Widely used in industries such as oil and gas, chemical, and power generation, its precise dimensions and strict manufacturing standards ensure compatibility and reliable performance in complex piping setups.

|

|

|

|

Specifications:

| Model Number: | ansi |

| Material | Stainless steel/Carbon steel/Alloy steel |

| Flange Size | 1/2" -200" / DN10-DN500 |

| Flange Type | Welding neck , Slip on, Blind , Long welding neck, Spectacle Blind |

| Flange Surface | Anti-rust oil, transparent paint , Black paint, Yellow paint, etc. |

| Connection | Welding, Threaded,Lap joint |

| Technical | Forged |

| Flange Package | Standard export packaging |

| Single package size | 2X2X2 cm |

| Single gross weight | 2.000 kg |

Applications:

Weld - neck flanges are widely applied in high - pressure and high - temperature piping systems. They are crucial in industries like oil and gas, petrochemical, and power generation. Due to their robust design, they offer excellent strength and leak - tightness. These flanges connect pipes securely, ensuring the integrity of fluid transfer systems. They also facilitate easy maintenance and replacement of components within the piping network.

Advantages:

Weld - neck flanges offer several advantages. Firstly, their integral hub design provides enhanced strength and stress distribution, making them suitable for high - pressure and high - temperature applications. Secondly, the smooth transition from the pipe to the flange reduces turbulence and potential leakage points. Additionally, they are highly reliable in critical systems due to their superior welding quality, ensuring long - term safety and stability in industrial piping.