優れた耐食性と長寿命

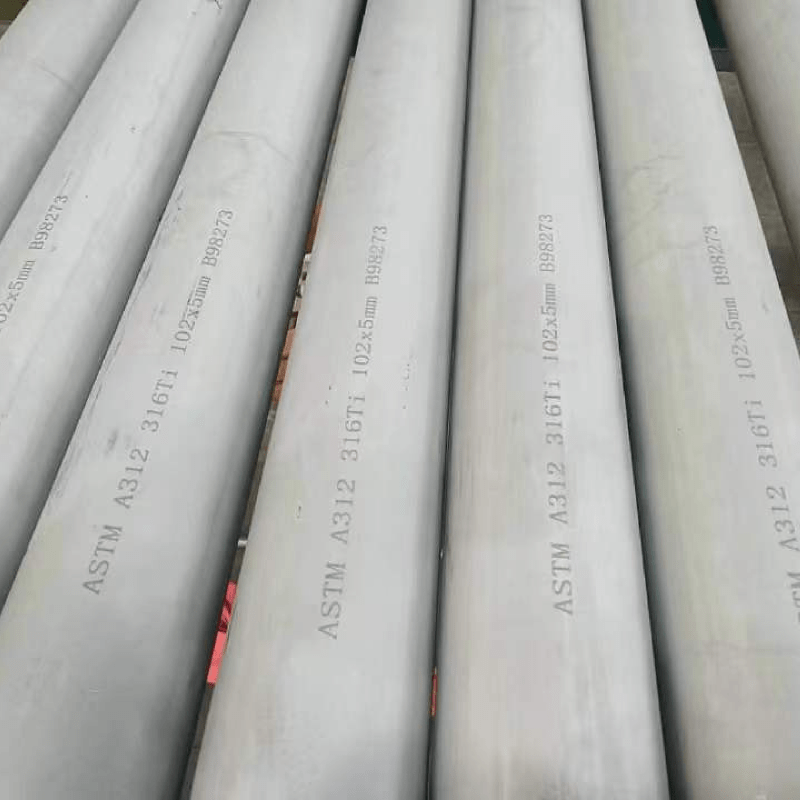

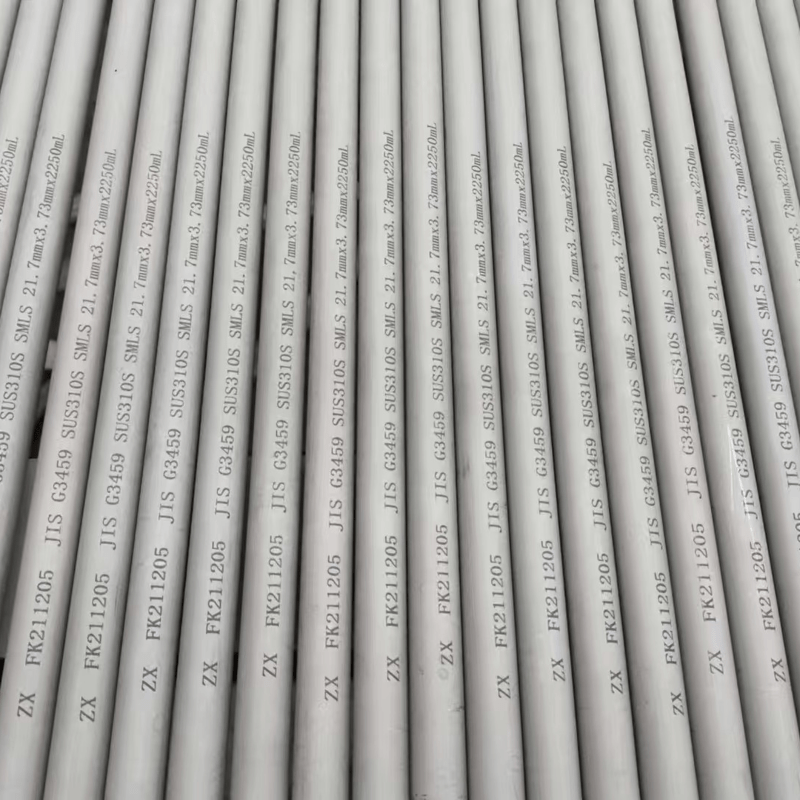

ステンレス鋼管の優れた耐腐食性は、クロムを豊富に含む組成に由来し、環境による劣化から継続的に保護する自己修復型の不動態皮膜を形成します。この固有の保護メカニズムは、酸性の化学処理から塩水噴霧の海洋環境まで、多様な使用条件下で効果的に機能します。この材料は過酷な条件下でも構造的完全性を維持する能力に優れており、標準的な用途では寿命が20年以上を超えることが多く、耐用年数が大幅に延びます。この長寿命性により、交換頻度が減少し、ライフサイクルコストが低減されます。不動態皮膜は機械的損傷後も自己再生する特性を持つため、保守の必要が最小限に抑えられ、信頼性の高い長期的な性能が確保されます。このような強力な耐腐食性により、システムの故障が重大な運用上または安全上の影響を及ぼす可能性がある重要な用途において、ステンレス鋼管は特に価値が高いです。