総合的な品質保証システム

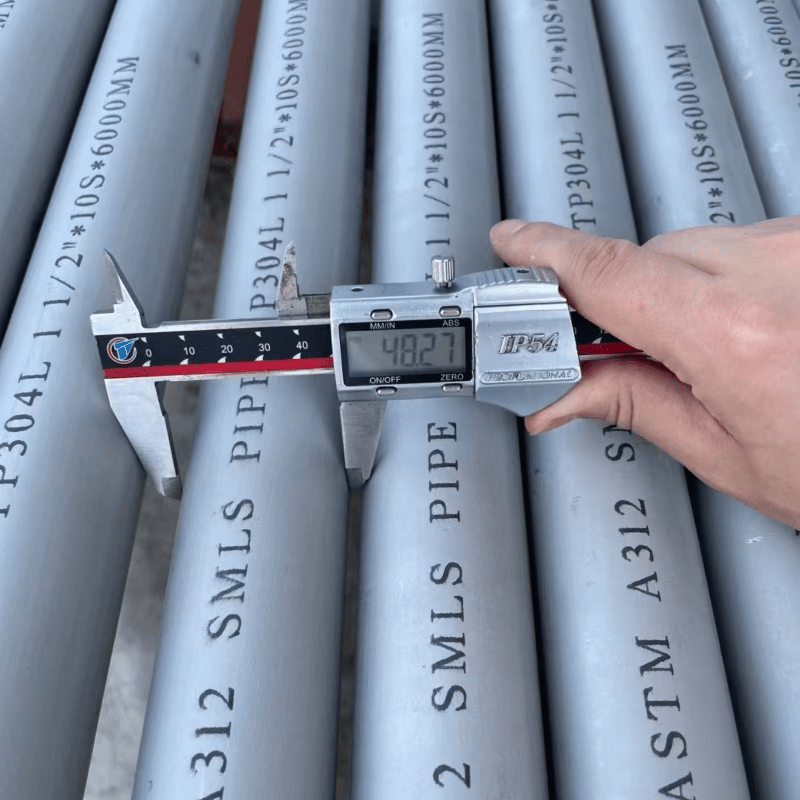

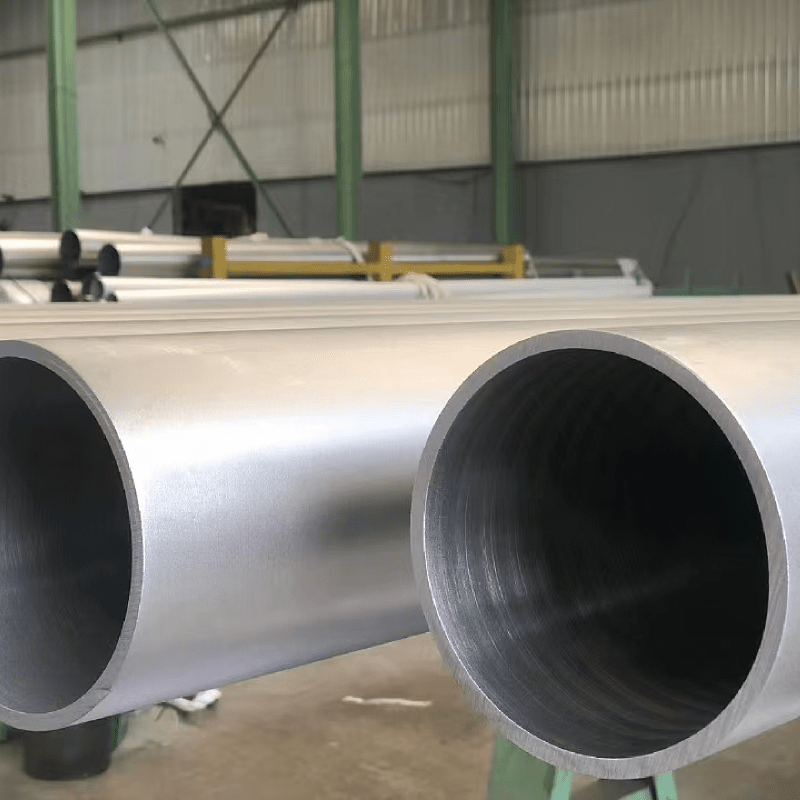

プロフェッショナルなフランジサプライヤーは、業務のあらゆる側面を網羅する堅牢な品質保証システムを導入しています。これらのシステムには、原材料の検証から完成品のテストまで、製造プロセス全体における複数の検査ポイントが含まれます。サプライヤーは、材料組成分析のための分光器、内部欠陥検出のための超音波検査装置、および精密な寸法測定ツールなどの高度な試験設備を活用しています。また、すべての品質管理手順と試験結果について詳細な文書記録を保持し、各製品の完全なトレーサビリティを確保しています。この包括的な品質保証アプローチにより、高価な故障を防ぎ、重要な用途において信頼性の高い性能を保証します。