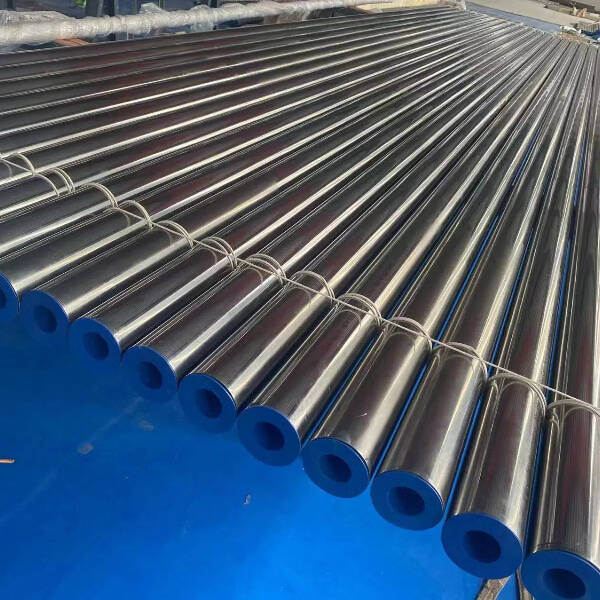

| Inconel 625 Pipes & Tubes are nickel-chromium-molybdenum-niobium alloys (UNS N06625) celebrated for exceptional corrosion resistance and high-temperature strength. With a composition of ~61% nickel, 21.5% chromium, 9% molybdenum, and 3.5% niobium (plus trace elements), they form a stable niobium carbides network, enhancing creep resistance up to 980°C. Their matrix resists pitting, crevice corrosion, and stress corrosion cracking in seawater, acids, and chloride environments. Boasting tensile strength ≥830 MPa and excellent weldability (no post-weld heat treatment needed), these pipes/tubes comply with ASTM B444/B829. They excel in offshore oil & gas equipment, chemical processing vessels, and aerospace fasteners, outperforming carbon steels in harsh media. Their ductility (elongation ≥40%) and thermal stability make them ideal for cryogenic to extreme heat applications, such as heat exchangers and nuclear reactor components. |

|

|

|

| Brand Name: BEALL |

| Place of Origin: Jiangsu, China |

| Section Shape: Round (or other shape) |

| Standard: ASTM/ASME/AISI |

| Delivery Time: 8-14 days |

| Processing Service: Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Outer diameter: 1/2''~60'' |

| Wall Thickness: as your request |

| Length: 1-12m, as your request |

| Packaging: seaworthy packing, or as your request |

| Payment Terms: TT 30% in advance, balance before the shipment. |