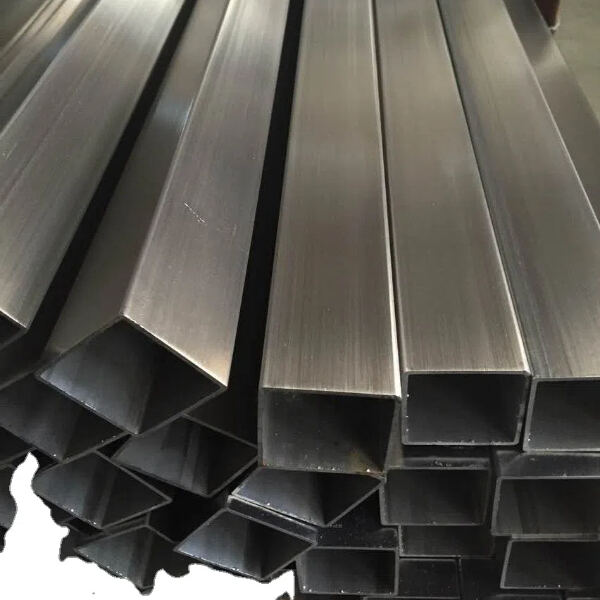

| Haynes 556 Pipes & Tubes are nickel-chromium-based multi-alloyed materials (UNS R30556) designed for exceptional corrosion and high-temperature resistance. Containing chromium, molybdenum, tungsten, and niobium, they resist pitting/crevice corrosion in chloride/fluoride-laden acids (e.g., HCl, HF) and maintain stability in sulfuric/phosphoric acids. With tensile strength ≥450 MPa at 650°C and oxidation resistance up to 1000°C (formation of Cr₂O₃-MoO₃ protective film), these pipes/tubes excel in hydrometallurgical reactors, flue gas scrubbers, and waste incineration systems. Compliant with ASTM B619/B622, they offer excellent weldability (TIG/MIG compatible) and formability, making them ideal for high-temperature acidic environments where standard alloys fail. |

|

|

| Haynes 556 Pipes & Tubes are nickel-chromium-based multi-alloyed materials (UNS R30556) designed for exceptional corrosion and high-temperature resistance. Containing chromium, molybdenum, tungsten, and niobium, they resist pitting/crevice corrosion in chloride/fluoride-laden acids (e.g., HCl, HF) and maintain stability in sulfuric/phosphoric acids. With tensile strength ≥450 MPa at 650°C and oxidation resistance up to 1000°C (formation of Cr₂O₃-MoO₃ protective film), these pipes/tubes excel in hydrometallurgical reactors, flue gas scrubbers, and waste incineration systems. Compliant with ASTM B619/B622, they offer excellent weldability (TIG/MIG compatible) and formability, making them ideal for high-temperature acidic environments where standard alloys fail. |