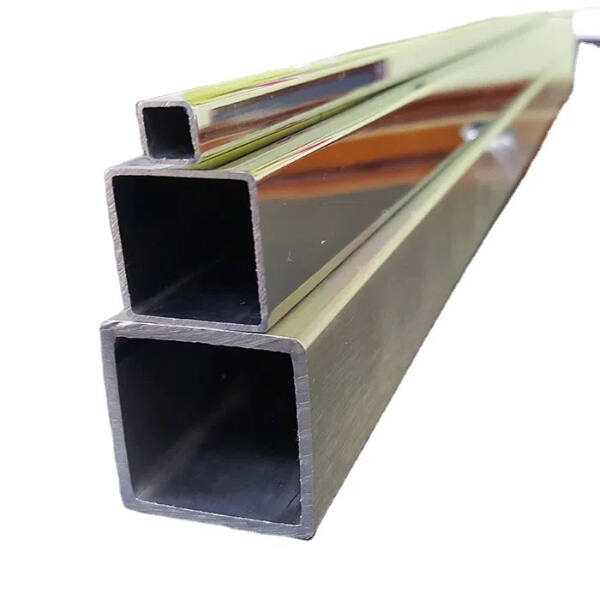

| Hastelloy S Pipes & Tubes are nickel-molybdenum-chromium alloys (UNS N06635) designed for high-temperature corrosion resistance. Containing ~65% nickel, 15-17% molybdenum, and 13-15% chromium, they offer excellent resistance to oxidizing and reducing acids, as well as stress-corrosion cracking in chloride environments. With a tensile strength ≥758 MPa and good creep resistance up to 1100°C, these pipes/tubes are ideal for chemical processing, petrochemical reactors, and high-temperature heat exchangers. Manufactured to ASTM B619 and B622 standards, they withstand harsh media like sulfuric acid and maintain mechanical integrity in extreme conditions. |

|

|

|

| Hastelloy S Pipes & Tubes are nickel-molybdenum-chromium alloys (UNS N06635) designed for high-temperature corrosion resistance. Containing ~65% nickel, 15-17% molybdenum, and 13-15% chromium, they offer excellent resistance to oxidizing and reducing acids, as well as stress-corrosion cracking in chloride environments. With a tensile strength ≥758 MPa and good creep resistance up to 1100°C, these pipes/tubes are ideal for chemical processing, petrochemical reactors, and high-temperature heat exchangers. Manufactured to ASTM B619 and B622 standards, they withstand harsh media like sulfuric acid and maintain mechanical integrity in extreme conditions. |