تعددية المواد المتفوقة

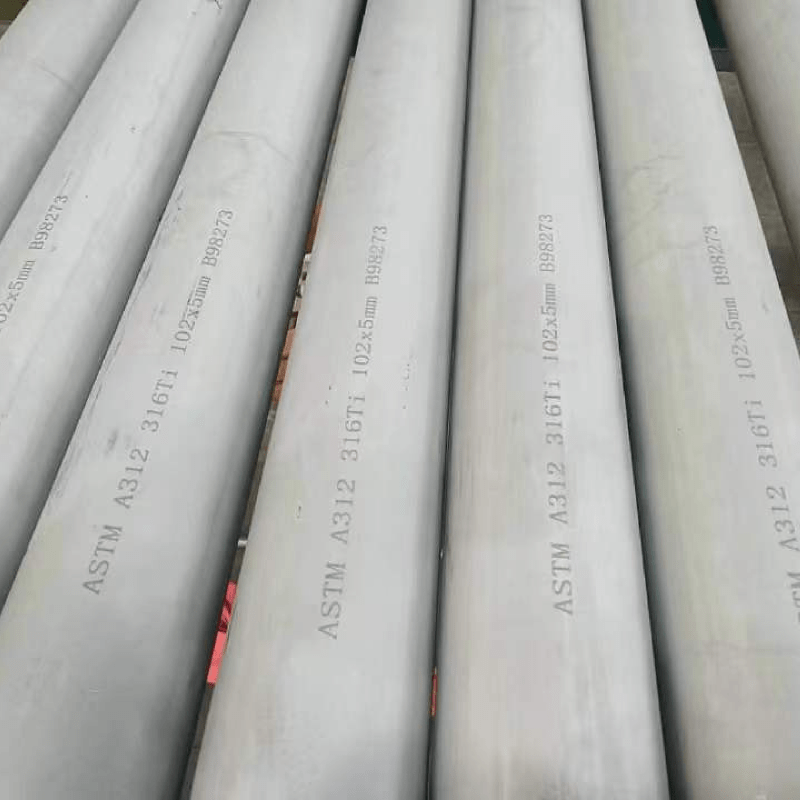

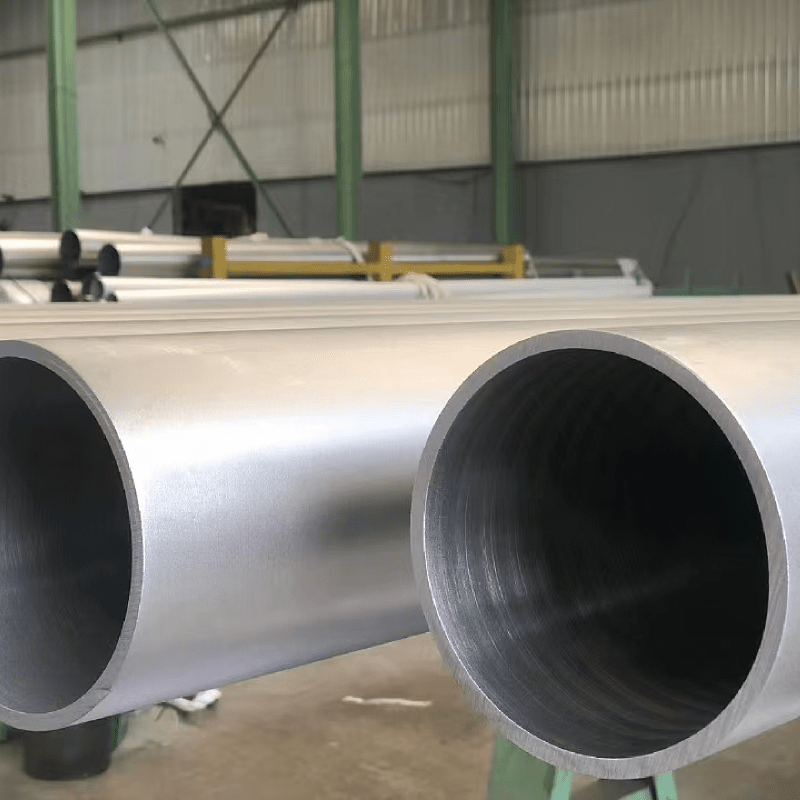

تُظهر وصلات الأنابيب تنوعًا استثنائيًا من حيث المواد، مما يوفر حلولًا لجميع سيناريوهات الاستخدام تقريبًا. وتتضمن المجموعة أصنافًا من الفولاذ المقاوم للصدأ تتفوق في البيئات التآكلية، حيث توفر مقاومة ممتازة للتدهور الكيميائي وتحافظ على السلامة الهيكلية في الظروف القاسية. كما تتميز وصلات الأنابيب النحاسية بموصلية كهربائية جيدة ومقاومة عالية للتآكل، ما يجعلها مثالية لأنظمة إمداد المياه وتطبيقات التدفئة. أما الخيارات المصنوعة من الفولاذ الكربوني فتوفر قوة متينة ومتانة عالية بأسعار تنافسية، وهي مناسبة للتطبيقات الصناعية العاملة تحت ضغط عالٍ. ويتيح توفر مواد مختلفة للمهندسين والمقاولين اختيار الخيار الأنسب بناءً على الظروف البيئية المحددة ومتطلبات الضغط واحتياجات التوافق الكيميائي.