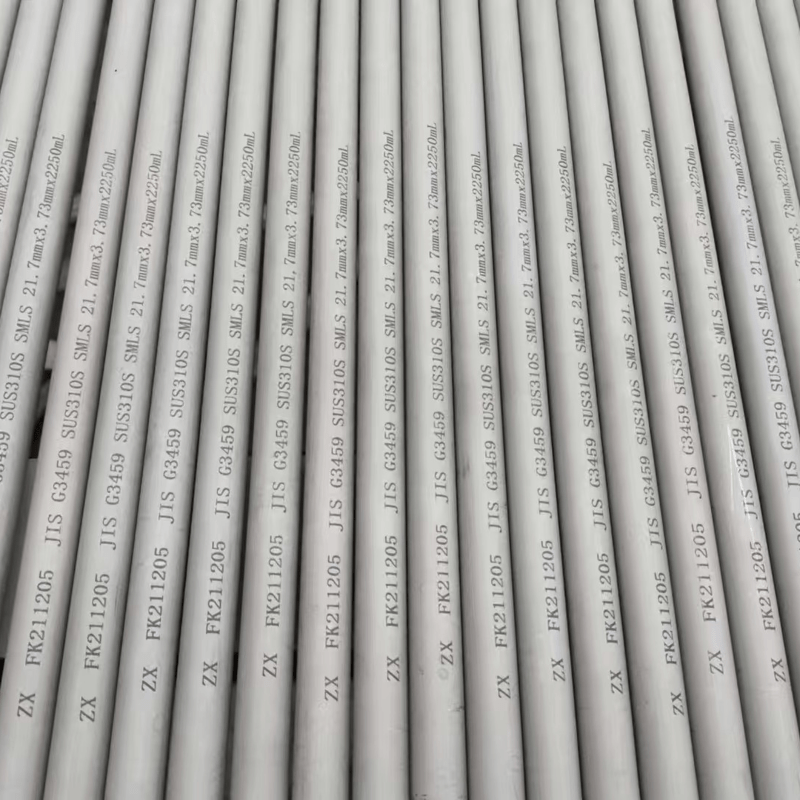

Superior Corrosion Protection

The exceptional corrosion resistance of stainless pipe fittings stems from their chromium-rich composition, which forms a self-healing passive layer when exposed to oxygen. This protective barrier prevents rust formation and chemical deterioration, even in aggressive environments containing acids, alkalis, and chlorides. The fittings maintain their structural integrity and appearance over extended periods, eliminating the need for protective coatings or frequent replacement. This inherent corrosion resistance translates to significant cost savings in maintenance and downtime reduction, particularly in coastal areas or chemical processing facilities where corrosion is a primary concern.