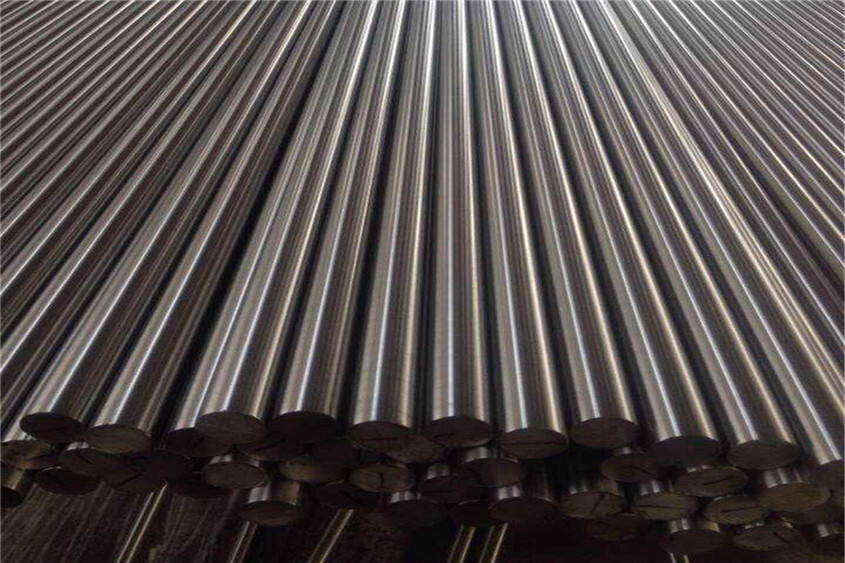

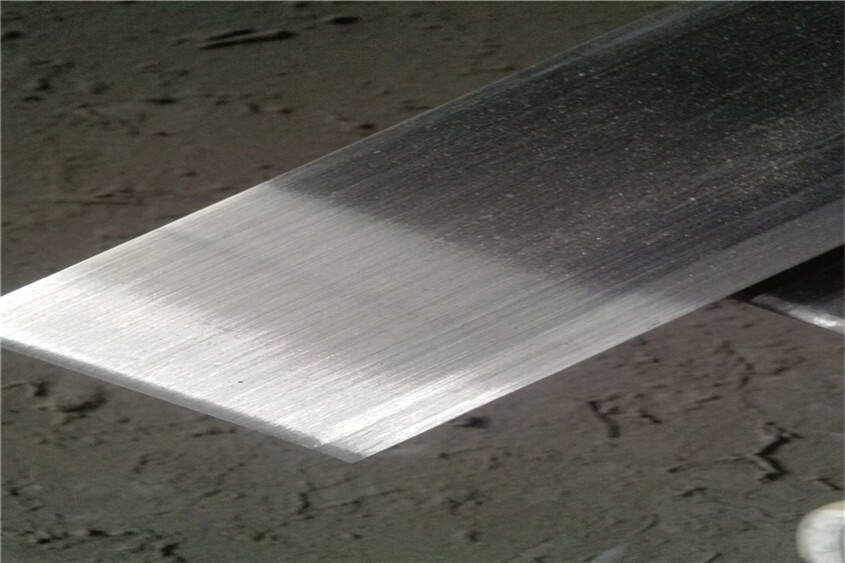

Superior Material Purity and Consistency

The hallmark feature of AMS 5662 lies in its exceptional material purity achieved through the sophisticated double vacuum melting process. This advanced manufacturing technique, combining vacuum induction melting and vacuum arc remelting, effectively removes unwanted gases and inclusions from the metal. The result is a highly refined microstructure with minimal segregation and improved chemical homogeneity throughout the material. This superior purity level directly translates to enhanced mechanical properties, including better fatigue resistance and improved toughness. The consistency in material composition and properties across different production lots ensures predictable performance in critical aerospace applications, reducing the risk of unexpected material behavior or component failure. The stringent control over impurity levels also contributes to better welding characteristics and heat treatment response, facilitating manufacturing processes and component assembly.